Selecting Materials: Laser Marking Machine Guide

Selecting Materials: Guide for Laser Marking Machines

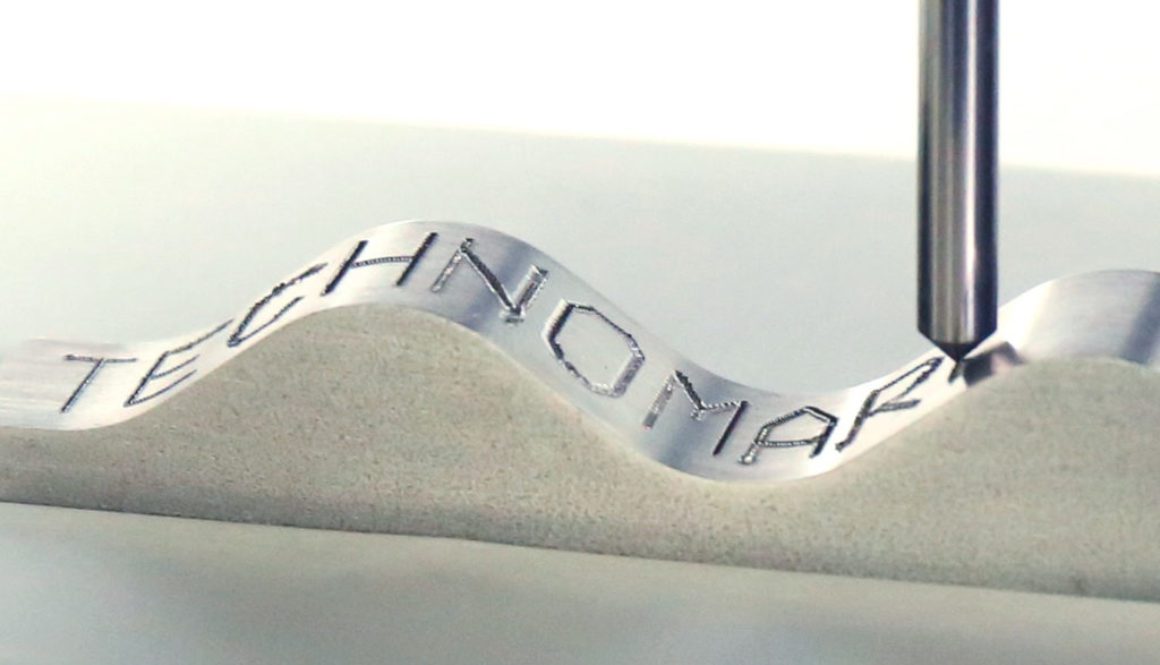

Laser marking machines are necessary in sectors where labels must withstand tough conditions and stay readable. When picking the right laser for the job, it really boils down to the materials you’re working with.

Whether you’re dealing with hard metals that demand precise, enduring marks or softer materials like plastics and wood that need a lighter touch, knowing the specific challenges and requirements of your materials is key.

In this article, we’ll break down how choosing the right laser based on your material can make a big difference in your operations.

The 2 Different Types of Laser Markings

Fiber lasers are known for their efficiency and precision. They intensify a simple seed laser into a powerful beam ideal for detailed cutting and welding. If you’re looking for a reliable and efficient machine with minimal downtime, fiber lasers might be the right choice.

CO2 lasers, on the other hand, use carbon dioxide to generate a beam that’s excellent for high-precision and intricate designs. They’re fast and versatile, perfect for projects that require quick turnarounds on a variety of materials, from metal to wood.

Materials Compatible With Laser Marking

Laser marking technology provides a flexible and effective way to engrave and mark various materials, each with distinct traits and ideal for specific uses.

From the natural beauty of wood, which provides a classic, warm finish, to the durability and precision required for laser-marked metals like stainless steel and aluminum, laser systems can cater to a variety of different materials.

Plastics offer a versatile canvas for laser marking thanks to their wide range of types. This allows for both clear and distinct markings, making it a flexible choice for various applications.

Specific types of materials that are compatible with laser marking systems include:

Metals:

- Stainless steel

- Steel

- Carbide

- Titanium

- Aluminum

- Gold

Plastics:

- ABS (Acrylonitrile Butadiene Styrene)

- Polycarbonate

- Polyamide

Other materials:

- Wood

- Ceramic

Understanding the properties of these materials can help you select the right laser marking system and ensure high-quality, lasting marks.

Factors in Choosing Material for Laser Marking

Choosing the right laser marking system means ensuring it works well with the materials you plan to mark or engrave. Different materials, such as stone, glass, or metal, require different lasers and power levels.

For instance:

CO2 lasers excel in engraving organic materials (like wood or glass), plastics, and certain metals, but they might struggle with stainless steel due to its high reflectivity.

On the other hand, fiber lasers, with their higher power output, are better suited for marking metals like aluminum, brass, and titanium. This is why identifying the surface material is important before buying a laser marking machine.

When choosing the appropriate laser marking machine for the materials in your production line, you should consider the following:

- Material properties: Different materials have unique absorption rates, heat resistance, and other characteristics that influence how you can mark them

- Desired outcome: The quality, depth, and durability of the marking significantly impact the choice of machine. These factors should align with your production line requirements to ensure optimal performance.

- Environmental considerations: The labeling must endure throughout the lifespan of the laser-marked product. In demanding applications, such as aerospace, exposure to elements and temperature variations can dictate the most effective marking method.

- Note: Aerospace components may require different marking approaches based on their specific use cases.

- Regulatory and safety standards: Different industries have varying regulations concerning part durability and traceability. Your chosen marking solution must comply with these standards while providing long-term reliability and accuracy.

How does laser markings compare to dot-peen marking in your industry?

Keep reading here for more marking solutions tailored to your specific needs!

Tips for Optimizing Material Choice and the Laser Marking Process

Understanding each piece of the “quality” puzzle when it comes to material preparation and handling for a laser-marked product is key.

Knowing how to use laser marking machines effectively can significantly improve your product’s outcome.

Here is a numbered list of key practices for matching material to machine:

- Surface preparation: Ensure the material surface is clean, free from oils, dust, or contaminants. Conduct test runs for materials with varied qualities or coatings to find optimal laser settings for consistent results.

- Laser parameter adjustment: Different materials and marking depths require adjustments in power, speed, frequency, and focus. Regular calibration and test runs on sample materials help fine-tune these settings for each specific task.

- Record-keeping: Maintain a log of the best settings for various materials and applications to minimize trial and error.

- Regular maintenance: Establish a maintenance schedule for cleaning lenses and mirrors, and ensuring moving parts are well-lubricated. Regular checks for wear or damage are also crucial.

- Use high-quality consumables: Invest in trustworthy lenses, mirrors, and laser sources. Regular inspections and timely replacements are key to sustaining peak laser performance and marking quality.

Technomark offers free tests on your parts to ensure that laser marking is the right solution. We can also provide training to help users with advanced marking settings.

Navigating Material Choices for Maximum ROI in Laser Marking

Laser marking machines stand out for their efficiency and lower energy use, delivering durable marks that other methods can’t match. When choosing the right material for your marking machine, consider every angle. Be thorough during the testing phase to ensure your investment is worth it when full-scale production begins.

Remember, taking the time to get these decisions right is not just about optimizing your process but also maximizing your return on investment. So dive deep, test thoroughly, and make informed choices to see the best results when you ramp up production.

Unlock Your Laser Marking Potential

Still wondering about laser marking?

Take this resource with you – it’s packed with insights and tips to help you make informed decisions and optimize your operations.

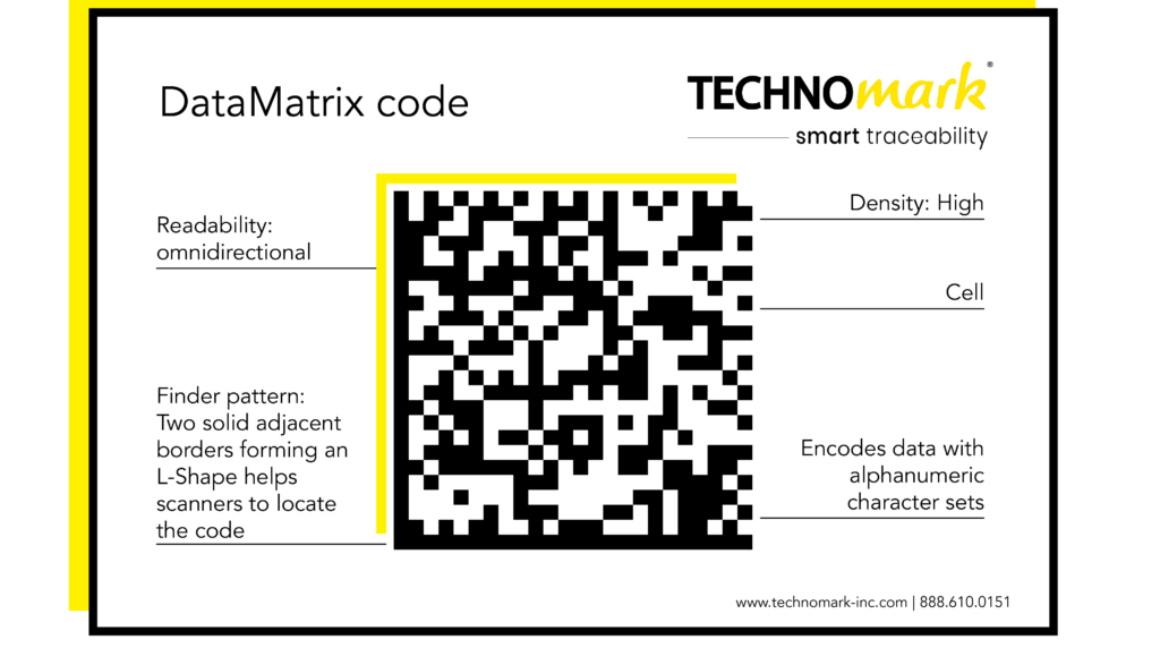

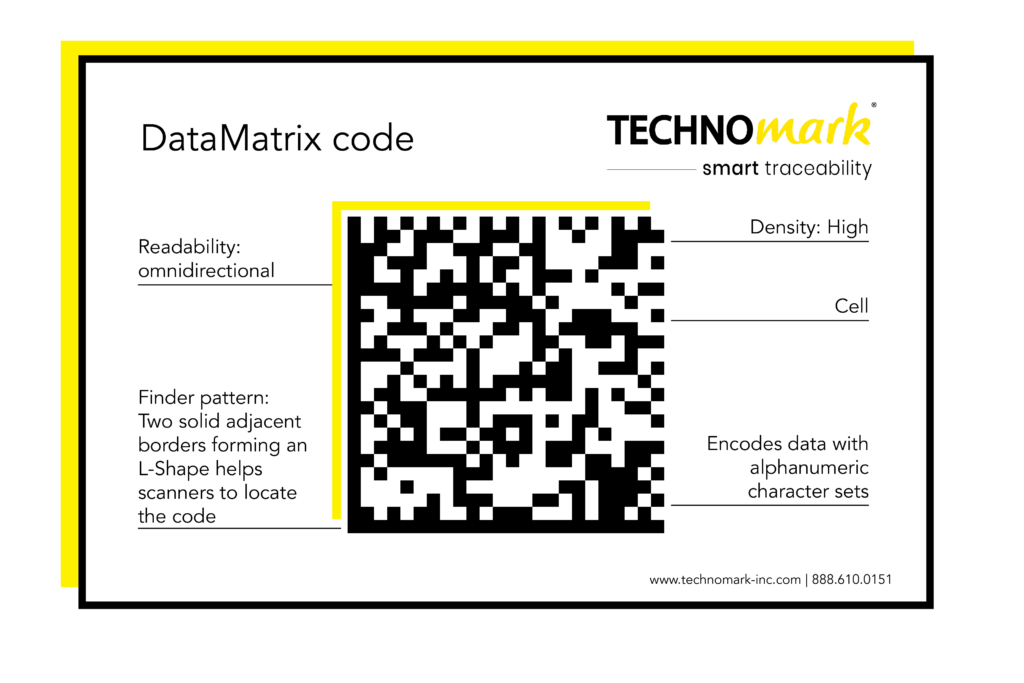

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.

Data Matrix codes are another type of two-dimensional barcode, but they are smaller and more compact than QR codes. They are often used in industrial settings, such as manufacturing and logistics, because they are highly durable and can be scanned even when damaged or dirty. Data Matrix codes are useful for tracking individual items or components throughout production, ensuring accuracy and efficiency.