The Ins & Outs of Industrial Laser Marking Machines

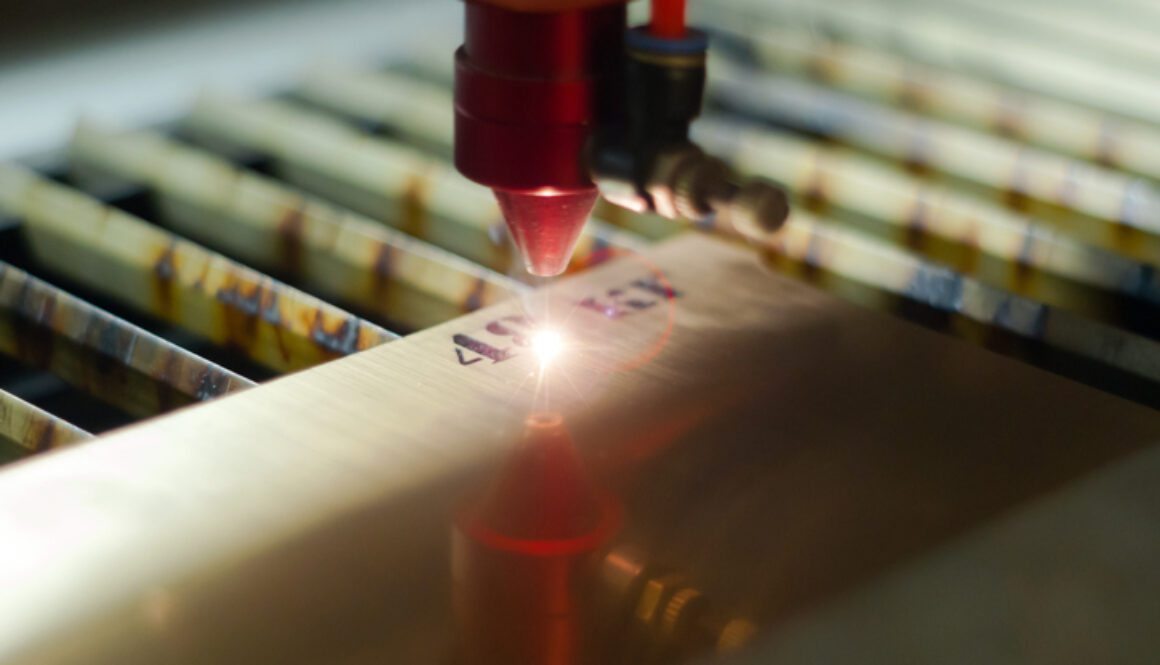

Laser marking is a versatile process that uses laser technology to create permanent marks on materials such as plastics, metals, and other surfaces. The process works by focusing energy and heat from the laser beam onto a given material, which causes chemical changes in the material’s surface layer. This creates impressions that are highly visible and oftentimes indelible.

A few of the factors that make up this process include:

1. Laser Type: Different types of lasers are used for different types of marking applications. Generally speaking, CO2 lasers can be used for engraving and polymers while fiber lasers are ideal for marking metals.

2. Material: Different materials may require different laser parameters or even completely different types of lasers to achieve desired results. It’s important to consider the material’s properties before selecting a laser type.

3. Quality Requirements: The quality requirements of the applied mark determine which parameters must be considered during laser processing to ensure accuracy and precision. Common laser parameters include:

- Pulse rate

- Line width

- Speed

- Power density

- Dwell time (the amount of time the laser is applied to a single spot)

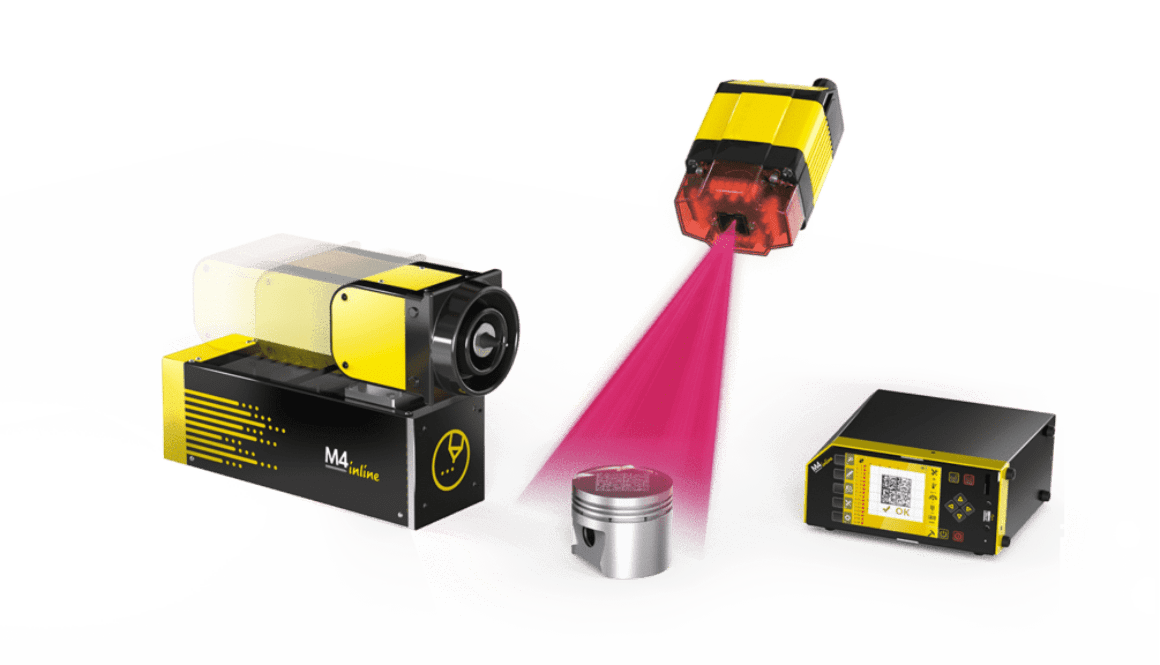

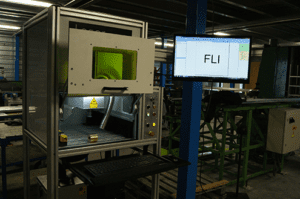

4. Equipment Used: Depending on your application needs there are many different kinds of industrial laser marking machines available on the market today – each with their own advantages and disadvantages that should be considered when making selection decisions.

Laser marking offers many advantages over traditional marking methods such as stamping, printing, and engraving. Laser marking is fast, accurate, and permanent. It can also be used to mark a variety of materials without the need for additional setup or alteration. The laser beam never touches the material being marked, making it possible to achieve high-precision marks with no significant post-processing required.

These features make laser marking ideal for precision parts and items that require both high accuracy and longevity in their markings.

For information on laser marking types, check out our blog:

Laser Marking Source | Laser Types & Selection Considerations – TechnoMark

Factors to Consider when Choosing a Machine

There are several factors related to the product line and marking requirements that must be considered when choosing a laser marking machine. Here we will dig a little deeper into some of those factors, including:

1. Marking requirements and specifications

2. Material compatibility

3. Marking speed and throughput

4. Maintenance and operational costs

5. Integration with existing production line

6. Safety considerations

1. Marking Requirements and Specifications

The marking requirements are important to consider when choosing among the options for high accuracy laser systems. The process should begin with an understanding of the specific needs of the product being marked—including size, shape, material, and desired end result. For example, if a product requires detailed engraving that is outside of the capabilities of some machines, then a different option may need to be chosen. Additionally, depending on the material being marked or engraved upon, different laser types may be more suitable than others in terms of speed and quality.

It’s also important to consider how frequently the machine will be used and how many products it needs to mark per hour or day.

This will determine not only which type of laser marking system is most suitable but also whether faster systems require higher maintenance costs. Keeping these factors in mind can help ensure that the right machine is chosen for the job.

2. Material Compatibility

The right laser marking system should be compatible with the materials that need to be marked or engraved. Laser engraving on stone, glass or metal will require different laser types and power. For example, a CO2 laser is suitable for engraving woods, plastics, and some metals but might not be able to mark stainless steel perfectly due to its higher reflectivity.

On the other hand, fiber lasers are more suitable for metals such as aluminum, brass and titanium due to their higher power output. Therefore, it’s important to consider which material needs to be marked or engraved before choosing a laser marking machine.

3. Marking Speed and Throughput

Faster laser machines can process more work in less time, allowing businesses to realize faster cycle times and higher throughput.

Moreover, higher throughput can also enable businesses to take on bigger jobs that require more items to be marked or engraved in shorter amounts of time. For example, if a business needs to engrave 1000 parts per day, it will need a laser marking machine with high speed and throughput in order to meet its daily production requirements.

4. Maintenance and Operational Costs

In addition to the other considerations when choosing a laser marking machine, businesses should also be aware of the associated maintenance and operational costs. Regular maintenance is key for keeping these machines in optimal condition, as well as ensuring safety during use.

Operational costs will vary depending on the type of material that is being marked or engraved, such as energy consumption levels and safety requirements that must be met. In some cases, the cost of consumables like lasers may also add up over time. To ensure that businesses get the most out of their investment, they should factor in all long-term operational costs when selecting a laser marking machine.

5. Integration with Existing Product Line

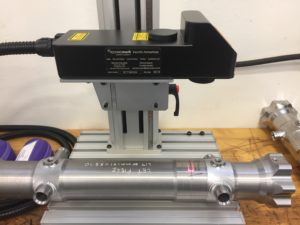

When integrating a laser marking machine into existing product lines, there are several factors that must be taken into consideration. The first consideration is whether a new machine is compatible with any existing product lines, and the potential for physical compatibility and system integration should be assessed beforehand. Next, the safety of any operators or users must be taken into account to ensure they can use the machine safely.

The laser marking machine should also be equipped with any necessary features for interacting with other production processes or products in order to guarantee seamless integration. It is also essential to think about the cost-effectiveness of installing such a machine and consider how it will fit within current budgets and operational costs.

6. Safety Considerations

Safety is an incredibly important factor when it comes to the implementation of laser marking machines. Not only should any potential machine be capable of providing safe conditions for operators, but it should also have advanced features such as motion sensors and emergency stop buttons in order to quickly respond in cases of unexpected events.

All machinery must conform to necessary safety standards and regulations both from the local legislation and from any international or industry-specific standards. Manufacturers must also provide extensive safety information about their products, including a detailed user guide that can help users understand how to safely operate the machine.

Applications of Industrial Laser Marking Machines

Industrial laser marking machines are used to mark metal parts with information such as serial numbers or expiration dates. Permanent laser marking helps these industries maintain their standards of reliability while providing a cost-effective solution.

In addition to the technical requirements of accuracy and longevity, lasers can also be used for more decorative applications such as engraving images or logos. Industrial laser machinery is increasingly becoming an important part of manufacturing processes in these high-tech industries due to its versatility, cost efficiency, and ability to create permanent markings with precision.

The following industries require reliable laser marking solutions to ensure long-lasting performance and accuracy:

- Automotive

- Aerospace

- Electronics

- Medical

A. Automotive Industry

Inventory management, quality control, and tracing defective parts are all typical uses of laser part marking in the automotive industry. Datamatrix codes effectively provide the information necessary for all of these processes and more. Marking on braking discs is one of the most common applications. However, laser marking systems can be effective for marking plastic as well.

B. Aerospace Industry

Laser Part Marking systems can mark on titanium, steel, and aluminum. Alphanumeric and 2D DataMatrix codes are ideal for aerospace applications, where tracing parts and identifying them are necessary at all times. Marking aircraft turbine blades is a prime example of the effective use of laser part marking.

C. Electronics Industry

Component identification, brand recognition, and counterfeit product reduction are all efficient applications of laser marking in electronics. This process is efficient for marking plastic connectors as well.

D. Medical Device Industry

Traceability and quality of care are priorities for the medical field, and laser marking provides an efficient way to improve both. From pacifiers to surgical instruments, the process improves the readability of product IDs.

Industrial Laser Marking Machine Selection | Consult the Experts

Now that you understand the various factors to weigh and the considerations that go into laser marking machine selection, you may have further questions. If you need the highly visible and permanent marks that laser marking machines provide, Technomark experts are available to discuss those questions, or consider this free resource:

Laser Marking Downloadable Form

"*" indicates required fields