Technomark Article Hub

Blog

The Difference Between DataMatrix Code and QR Code

Industry codes are used for a number of processes in the manufacturing industry, but perhaps the most critical application is part marking. Part marking can be used to identify and track parts within production systems and supply chains, and there are many different types of industry codes that can be used for this purpose. DataMatrix […]

Shining a Light on Laser Precision: Fiber Lasers vs. CO2 Lasers

In today’s fast-paced industrial landscape, precision is not just a luxury—it’s a necessity. Laser marking technology, heralded for its unparalleled accuracy and versatility, has revolutionized industries from aerospace to consumer electronics. As with any technological innovation, there are choices to navigate. Among the most debated is the match-up between Fiber Lasers and CO2 Lasers. Both […]

Electromagnetic Portable Dot Peen Marker: Will It Fit Your Production Line?

The technology associated with direct part marking has been steadily advancing over the years. Instead of having to be anchored to a workstation, users can now easily take their marking systems wherever they need them. This can be key for the food & beverage industry, for example, which is making a concerted effort to improve […]

SOUTHTEC 2023 | Come See Technomark!

When it comes to diverse industries, SOUTHTEC is one of the four manufacturing trade shows in the Manufacturing Technology Series held in North America, intended to allow exhibiting companies the opportunity to connect with new clients and those in attendance to navigate networking opportunities. Discover the next evolution in advanced manufacturing; register today! SOUTHTEC will […]

The Ins & Outs of Industrial Laser Marking Machines

Laser marking is a versatile process that uses laser technology to create permanent marks on materials such as plastics, metals, and other surfaces. The process works by focusing energy and heat from the laser beam onto a given material, which causes chemical changes in the material’s surface layer. This creates impressions that are highly […]

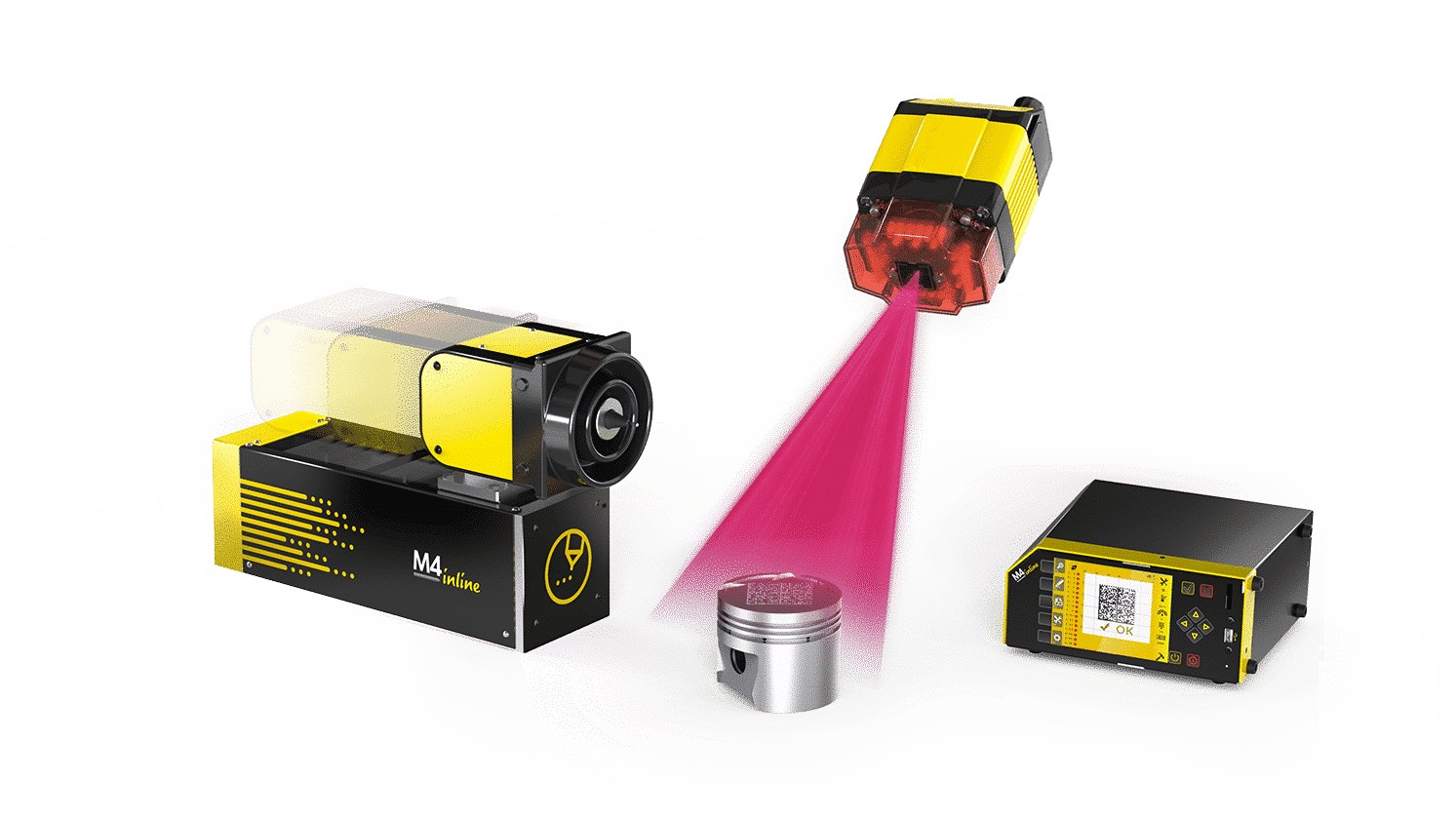

Industrial Marking Systems: Connectivity Options for M4 Inline

Industrial marking systems are automated solutions used to permanently mark a variety of materials, including plastic, and metal. They can provide a high degree of accuracy and quality in the markings they produce. Industrial marking systems such as the M4 Inline can be used for a variety of applications including product identification, traceability, part numbering, […]

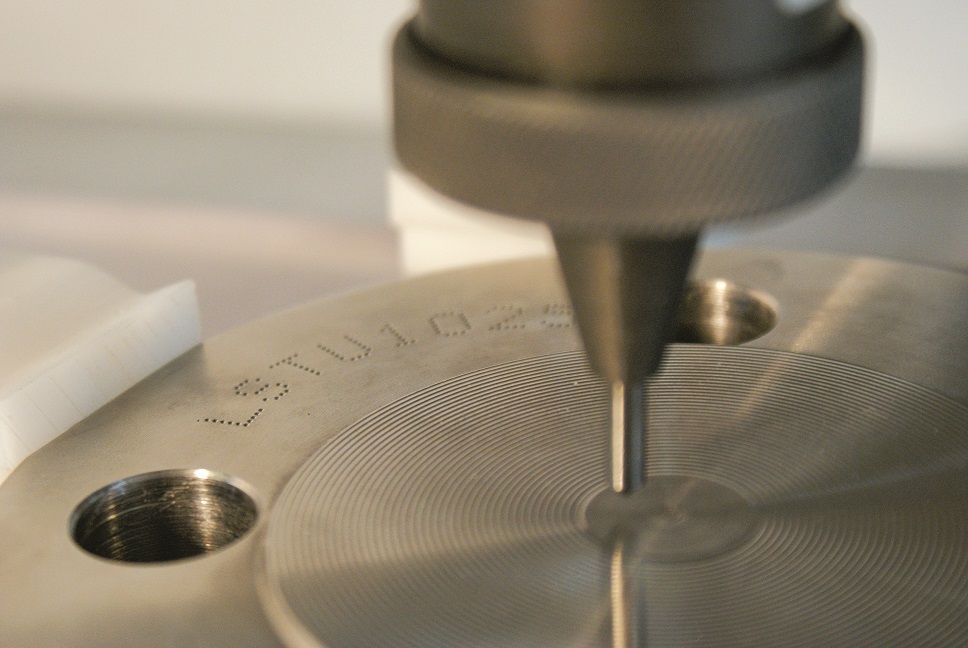

10 Things to Know About Dot Peen Marking Machines

The use of dot peen marking machines is prevalent in various industries. This popularity is due to the number of different configurations possible, including mixed-use where portable can become integrated in a short amount of time. What is Dot Peen Marking? Dot peen marking is a process utilizing either electromagnetic or pneumatic force to […]

Industrial Metal Engraving Machine for Custom-Use Cases

Customized part marking is essential for the successful production of parts in a variety of industries. By applying unique identifiers to each part or component, manufacturers can ensure precision in their production process while ensuring traceability throughout product life cycles. An industrial metal engraving machine provides that capability during the production process. Part marking is […]

EASTEC 2023: TNA is Prepped

Are you a manufacturing professional looking to stay ahead of the curve? If so, EASTEC 2023 is the event for you! This three-day conference and expo will allow attendees to learn from industry experts, explore new products and technologies, and gain valuable insights into modern manufacturing processes. Technomark will be in Booth 3157 […]

Direct Part Marking 101 | Automotive Component Traceability

The number of components used to manufacture vehicles has doubled over the past decade. This means more parts to keep in inventory track during production evaluate throughout the life cycle to pinpoint issues Automotive part marking requirements are intended to help with all of the above processes. This means accuracy and readability are crucial for […]