Technomark Article Hub

Blog

Data Matrix vs QR Codes: Choosing the Right Code For Your Needs

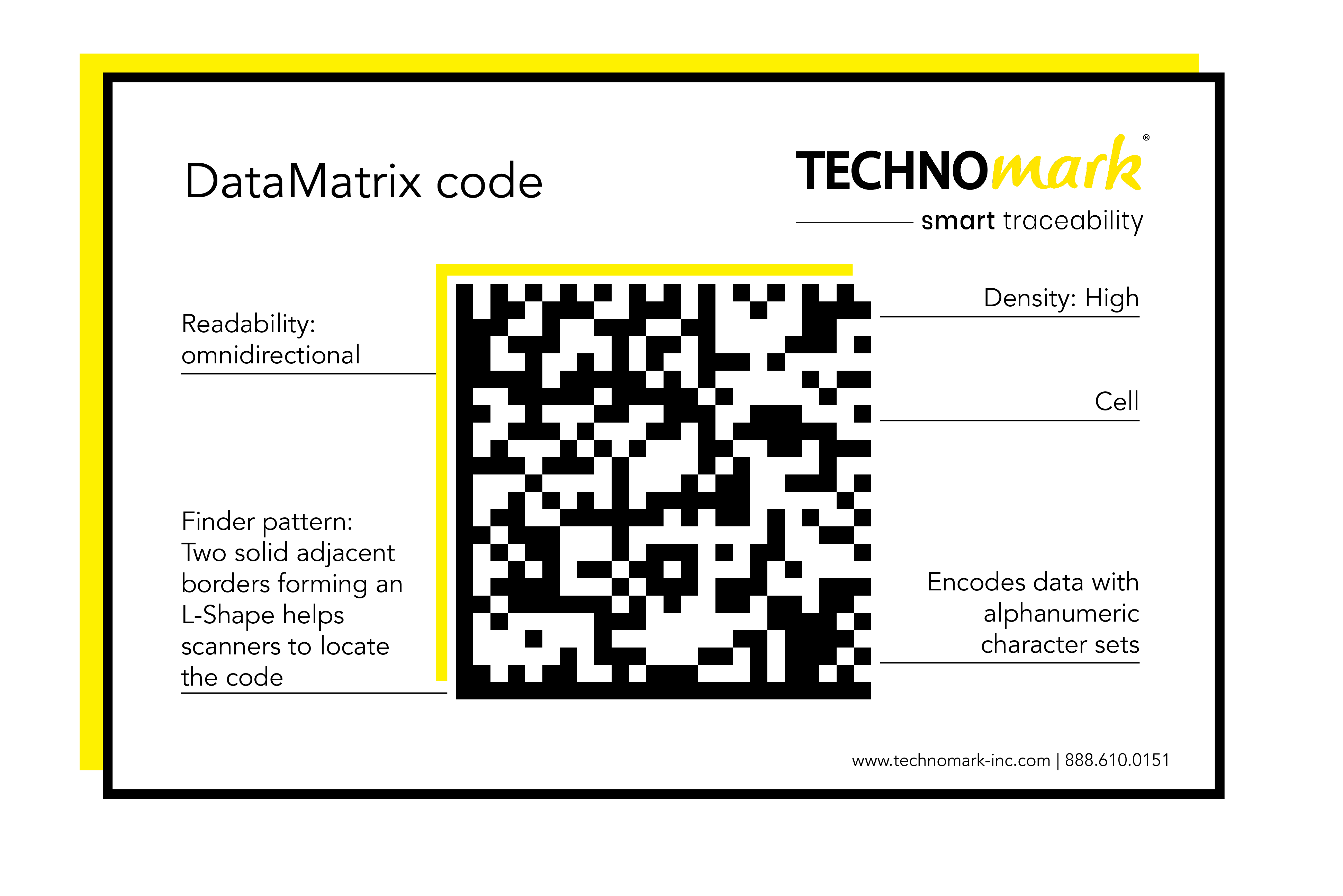

Have you ever wondered about the small, square barcodes often found on electronic devices, tools, and appliances? While they might resemble QR codes, they’re actually Data Matrix codes, essential components of modern manufacturing processes. Unlike QR codes, primarily used for consumer-facing applications like websites and social media, Data Matrix codes are designed for efficient data […]

5 Industrial Laser Marking Applications to Know

What commonalities do DVD players, checkout lines at the grocery store, and industrial marking machines all share? Lasers. But alas, not all lasers are the same. Do you know what L.A.S.E.R. stands for? Light Amplification by Stimulated Emission of Radiation. In other words, it’s a highly concentrated beam of light. Lasers consist of a: Gain […]

The Science Behind Industrial Laser Marking Systems: Understanding Material Interactions

Industrial laser marking systems are used across a wide range of industries and trusted for precision and accuracy to provide marks that are easy to read and stand up to wear and tear over time. Laser marking machines are capable of marking on a variety of materials, but the material influences the adjustments that need […]

Buddy, the Portable Dot Peen Marking Machine, is now available in 120

Buddy, the Dot Peen Marking Machine controlled by a smartphone, is now available in both 60 and 120. Available for months in a 60, a larger marking window is now added to the range to meet the needs of an increasing number of users. 60 or 120, make your choice! Press Release The new 120 […]

Laser Etching vs. Engraving: What to Know

Laser marking, also known as laser engraving or laser etching, is a precise and permanent method of adding marks or designs to various materials. It uses a high-intensity laser beam to alter the surface of the material, resulting in marks that can range from logos and text to intricate patterns. With both etching and engraving, […]

Unlocking the Potential: Increasing Productivity with Automated Dot Peen Machines

In the rapidly evolving landscape of industrial manufacturing, the adoption of cutting-edge technologies is not just a trend but a necessity for staying competitive. Among these, dot peen marking technology has emerged as a cornerstone for a myriad of industries, underscoring its critical role in product identification, traceability, and quality control. Dot peen machines, which […]

6 Tips for Choosing the Best Laser Marking System for Your Business Needs

Laser marking systems provide reliability and long-term marking solutions for commercial and industrial applications, which resolves concerns about component tracking for many industries where the product is exposed to extreme heat or other conditions that cause wear and tear. Choosing the best laser marking system for your production line means weighing the various factors that […]

Choose for Your Application: The Right Marking System in Industrial Facilities

Part marking systems are crucial across various industries for tracking, identification, quality control, and regulatory compliance. Two popular methods for part marking are dot peen marking and laser marking. Each has its advantages, disadvantages, and typical applications based on factors such as material compatibility, precision, cost, and durability of the mark. Here’s a detailed discussion […]

Direct Part Marking 101 | Part Marking Specifications for Defense and Military

Direct Part Marking (DPM) is a process utilized by various manufacturers to improve the traceability for the parts they create, and also to cut down on data entry errors and issues related to safety, warranty, and liability. For defense and military applications, part marking specifications streamline the process of identifying parts throughout the manufacturing process; and […]

Efficiency in Dot Peen Marking Systems Automation

Effective part-marking is indispensable for ensuring seamless component traceability in the industrial manufacturing sector, particularly when dealing with large quantities. Among the various part-marking options available, Dot Peen marking technology has stood out as a preferred solution over the years. Dot Peen marking machines use electromagnetic or pneumatic force to rapidly oscillate a stylus, […]