News

TECHNOMARK Partners with BAND-IT

TECHNOMARK and BAND-IT join forces to offer manufacturers and MRO facilities total integrated solutions for permanent marking of metal ID bands used for asset tracking and quality control.

Technomark North America has partnered with BAND-IT Identification Solutions to provide a permanent marking solution for BAND-IT metal ID bands in a high-volume production environment.

BAND-IT colored bands are used for frac iron recertification, asset management, and other visual identification programs. BAND-IT COLOR-IT® technology resists weathering and color fading, with 16 stocked colors available for same-day delivery and custom powder coating available for non-standard colors. BAND-FAST® preassembled band and clips allow for a safe, quick installation.

BAND-IT marking integrations are available for both the Multi-4 dot peen marking system and Graphix laser marking workstation with 3-up BAND-IT metal ID band loading fixture. The custom tooling solutions for Technomark industrial marking equipment increase production throughput and lower total cost of ownership.

Technomark has been operating and supplying expertise with industrial marking equipment since 2000. In 2018, Technomark established a direct OEM presence in the USA with the opening of Technomark North America. Today, Technomark North America is the only OEM of dot peen and laser marking systems with USA headquarters located in the south-central United States. Our centralized location lowers your total cost of ownership (TCO) by reducing shipping costs and delivery lead times, propelling Technomark to become the fastest-growing brand of permanent marking systems in the Americas region.

BAND-IT, a unit of IDEX Corporation, is the world’s leading designer and manufacturer of engineered fastening solutions. Whether it’s your family driving cross-country, workers on an oil rig at sea, astronauts in space, or military troops deployed around the world, the equipment that moves them has been designed for safety and security under harsh conditions. That’s why airbag manufacturers, energy companies, the aerospace industry and our own military trust the quality, durability and diverse fastening capabilities of BAND-IT clamps. When it’s not just mission critical, but mission crucial, it better be BAND-IT!

For more information, contact us at info@technomark-inc.com

TECHNOMARK North America joins forces with SLINED Automation & Robotics

TECHNOMARK North America has joined forces with SLINED Automation & Robotics to expand its range of capabilities for process automation, industrial part marking and traceability in order to meet the needs of medical device manufacturers who must comply with FDA requirements for Unique Device Identification (UDI).

TECHNOMARK is a leading OEM of direct-part-mark (DPM) machinery centered on two core technologies: dot peen and laser marking. SLINED Automation & Robotics is an engineering company with fully integrated in-house capabilities for design and fabrication of manufacturing automation solutions with domain expertise in the medical device industry.

“Since 2000, TECHNOMARK’s innovative modular design concept for direct part marking has lowered Total Cost of Ownership for our customers,” said Eric McDaniel, President of TECHNOMARK North America. “Now thanks to the partnership with SLINED Automation & Robotics, TECHNOMARK brings even greater value to our customers by offering a single-source solution for all of their manufacturing automation needs.”

To learn more about TECHNOMARK’s complete range of custom integrated solutions for industrial part marking and traceability, please visit https://www.technomark-inc.com/custom-made/

To learn more about the complete range of capabilities for manufacturing automation offered by SLINED Automation & Robotics, please visit http://slined.com/

TECHNOMARK North America Joins the COVID Coalition

The goal of the COVID Coalition is to match healthcare workers in urgent need of medical equipment and supplies with manufacturers who have 3D printing capacity to quickly ramp up production of mission critical items.

TECHNOMARK North America has partnered with Stratasys as a charter member of the COVID Coalition to help organize a coordinated industry response to the COVID-19 public health crisis. The objective of the COVID Coalition is to match caregivers in urgent need of medical equipment and supplies with manufacturers who have 3D printing capacity that can be repurposed to produce mission critical items such as face shields, N95 masks, and respirator components. To learn more about how you can get involved with this effort, please

register at https://go.stratasys.com/lp-stratasys-helps.html

TECHNOMARK North America is the official OEM supplier of TECHNOMARK brand dot peen and laser marking equipment in the USA, including the Multi4 dot peen and GRAPHIX laser marking systems. Strategically located in the south-central USA (Houston metro area), TECHNOMARK North America provides sales, product training, technical support, local inventory, and repair services to users of TECHNOMARK brand industrial marking machines in the Americas region. To learn more, please visit www.technomark-inc.com

For more information, contact us at info@technomark-inc.com

TECHNOMARK Establishes Direct OEM Presence in the USA

CONROE, TEXAS – TECHNOMARK, a leader in permanent marking and industrial traceability solutions, is pleased to announce that sales and support for TECHNOMARK brand dot peen and laser marking machinery is now available on an OEM-direct basis in the USA.

Since 2004, TECHNOMARK has gone to market in the USA through a network of independent distributors and resellers. “In response to our valued customers who prefer to work directly with the OEM, TECHNOMARK opened its USA distribution center in 2018,” explains Eric McDaniel, President of TECHNOMARK North America. “More and more, global manufacturers demand that suppliers offer uniform product quality, after-sales support, and pricing programs – no matter where in the world they are operating.”

While the company still maintains a reseller network in the USA, users of TECHNOMARK brand industrial marking machines will now have the option to establish an OEM-direct supplier relationship on future purchases of machines, accessories, spare parts, and repair services for all Multi-4, M4 Inline, and FlexMark dot peen marking systems as well as GRAPHIX laser marking systems.

Strategically located in the south-central USA (Houston metro area), TECHNOMARK North America provides sales, product training, technical support, local inventory, and repair services to users of TECHNOMARK brand industrial marking machines in the Americas region.

For more information, contact us.

Here We Grow Again — TechnoMark North America Welcomes Luc Muller

TechnoMark North America is pleased to announce that Luc Muller has joined Team TNA in the position of Quality Manager – USA.

TechnoMark North America is pleased to announce that Luc Muller has joined Team TNA in the position of Quality Manager – USA.

Since 2012, Luc has served TechnoMark Group in diverse roles ranging from mechanical and industrial engineering to quality management.

In 2013, Luc oversaw the expansion of TechnoMark manufacturing operations in Saint-Chamond, France and was responsible for the organization of process and methods in support of production launch activities for the laser marking product line.

In 2015, Luc moved to Japan as the Technical Support lead for TechnoMark customers located in the Asia-Pacific region. Working on a 2-year assignment with TechnoMark’s distribution partner in Japan, Luc was tasked with providing product training to all staff members and conducting a technical survey of the local installed base of customers with the aim of growing market share in the region.

In 2017, Luc returned to TechnoMark world headquarters located in La Talaudière, France and was promoted to the position of Operations Quality Manager. In this role he was directly responsible for managing customer warranty claims as well as the development and implementation of continuous improvement initiatives within TechnoMark manufacturing operations.

Going forward, Luc will be based at TechnoMark North America headquarters located in Conroe, TX and will be an excellent support resource for customers of TechnoMark brand dot peen and laser marking systems in the USA. To learn more, please visit www.technomark-inc.com

Welcome, Luc Muller!

Here We Grow Again — TechnoMark Adds 20+ Year OEM Sales Veteran

Mike brings nearly 25 years of experience in distribution and direct-OEM sales, including broad experience in the permanent marking industry. He’s well-regarded by customers for his professional integrity, attention to quality, product and applications knowledge, and commitment to long-term supplier partnerships.

Mike will remain based in the Charlotte, N.C., area to best serve south-central and southeastern customers. His industry experience will be an excellent resource for customers of TechnoMark dot peen and laser marking systems in the region.

Join us in welcoming Mike to the TechnoMark team!

If you have industry or product questions for Mike or another member of the TechnoMark team, contact us today.

TECHNOMARK North America invites you to SOUTHTEC 2019

Booth: 1939

TECHNOMARK is a leading OEM of high performance industrial traceability solutions centered on two core direct-part-mark (DPM) technologies: dot peen and laser marking. TECHNOMARK’s modular design concept facilitates product integration with existing manufacturing processes while ease-of-use and system reliability maximize production uptime and lower total cost of ownership. Located in Conroe, Texas (40 miles north of downtown Houston), TECHNOMARK is the only OEM of industrial marking machines with North American headquarters in the south-central USA.

Products

GRAPHIX Laser Marking Workstation

GRAPHIX is an ideal solution for permanent marking of components in a low-volume, high-mix production environment. The space-saving, all-in-one design incorporates the laser marking head, embedded Windows PC, and electronic control system into a fully-integrated package that can be placed on a benchtop. Alternatively, the workstation can be placed on a mobile marking cart for deployment in a flexible manufacturing environment. An optional side-access opening permits insertion of bar stock, tubulars, or other oversize parts into the interior of the workstation enclosure for laser marking while maintaining a Class I safety rating. GRAPHIX is also available with standard and heavy duty rotary axis options that are plug-and-play and permit 360° component marking.

NEW for SouthTec 2019, TECHNOMARK has partnered with COGNEX to develop an integrated barcode reader package for the GRAPHIX laser marking workstation. To learn more, please see our announcement on LinkedIn at https://lnkd.in/eBR3RZp

The DataMan 370 series fixed-mount barcode readers solve challenging direct part mark (DPM) applications with advanced decoding algorithms, integrated lighting, and auto-focus liquid lens technology. To learn more about the DataMan 370, please visit COGNEX on the web at https://lnkd.in/e5mz_69

Available as an upgrade with the standard GRAPHIX laser marking system, TECHNOMARK lowers your Total Cost of Ownership (TCO) with an all-in-one solution for laser marking and reading 2D data matrix and QR codes marked directly onto high-value components for full item-level traceability.

M4 Inline – Integrated Dot Peen Marking System

M4 Inline comes standard with on-board PLC logic thanks to a 16-way user bus card, allowing the marking system to control other peripheral devices upstream and downstream from the marking process. The 16 discrete I/O points are fully digital and user-configurable according to the needs of a given production process, lowering total project cost by eliminating the need for an external PLC host control system. The all-electric design of M4 Inline also eliminates the need for compressed air, while TECHNOMARK’s patented IDI Mark feature permits marking of text onto curved or complex surfaces with even depth of marking and no character distortion. The compact marking head is ideal for mounting into tight spaces, while the machine control box can be rack-mounted in either a vertical or horizontal orientation.

An optional programmable linear index for the marking head is stepper motor driven for precision control and fully integrated with the user interface of the M4 Inline control box, accelerating the engineering development time on your next custom automation project. To see a demonstration video of M4 Inline, visit TECHNOMARK on the web here.

NEW for SouthTec 2019, TECHNOMARK has partnered with COGNEX to develop an integrated barcode reader package for the M4 Inline integrated dot peen marking system. The bar code reader package is based on the DataMan 260 fixed-mount ID reader and is driven by the on-board PLC logic of the M4 Inline control box for a complete DPM marking and reading solution. To learn more about the COGNEX DataMan 260 fixed-mount ID reader, please visit COGNEX on the web at https://www.cognex.com/products/barcode-readers/fixed-mount-barcode-readers/dataman-150-260-series

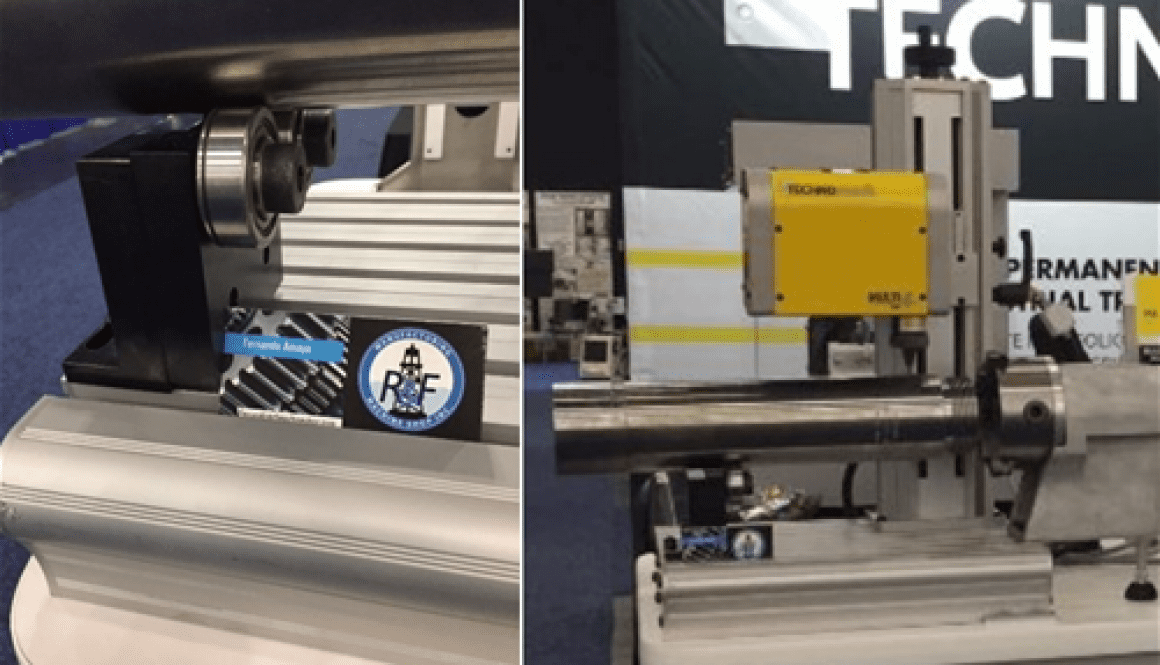

Multi-4 Modular 4-in-1 Dot Peen Marking System

NEW for SouthTec 2019, TECHNOMARK has partnered with R&F Machine Shop and Manufacturing of Conroe, TX to develop the new roller V-block part support for the Multi-4 dot peen marking system. When used with the Multi-4 High Capacity rotary D axis, the roller V-block part support provides additional stability for radial marking of tubular components measuring greater than 24″ in length and up to 5″ OD.

To learn more, please see our announcement on LinkedIn at https://www.linkedin.com/posts/ericmcdaniel_technomark-north-america-has-partnered-with-activity-6515789295201116160-T050