DISCOVER

M4 Inline

The M4 Inline Dot Peen marking solution has been specially designed to be easily integrated into automated manufacturing processes.

Equipped with innovative features and controlled by various means (such as the external control unit, serial link, “micro-contact” or even through an ethernet network), our customizable configuration allows for easy integration in production lines.

Electromagnetic Dot Peen marking designed to fit into your production chain

Designed for integration

Each axis is equipped with a ball bearings guide and a translation system with automatic play adjustment

Significant time savings for installation and productivity

Thanks to its 16-way card

Can be used in vertical or horizontal position

Thanks to long lasting diodes

Practicality

2 possible fixing zones for connection of the marking head, as well as the many standard connectors (Ethernet, RS232, USB)

M4 INLINE CONTROL UNIT

The solution for

production lines

- HD color screen

- Maintenance menu

- USB keyboard

- Advances connectivity

- Horizontal or vertical installation

- Multilingual software

- Large memory capacity

M4 INLINE AUTOMATION PACK

The solution dedicated to automated processes

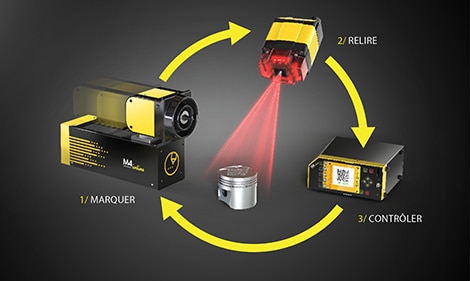

M4Inline Automation Pack, a complete solution including: dot peen marking equipment (M4Inline), translation unit (linear axis), integrated automation (16-channel card) and proofreading and information processing system

- Several sizes available

- Linear axis

- Super-fast travel time

- Multi-position use (horizontal, vertical, or hanging upside down)

- 2 operating modes (automatic or expert)

- Protective bellows

- Proofreading function (OK/NOK)

- Plug&Mark*

*single power cable between axis and control unit

PRODUCT ADVANTAGES

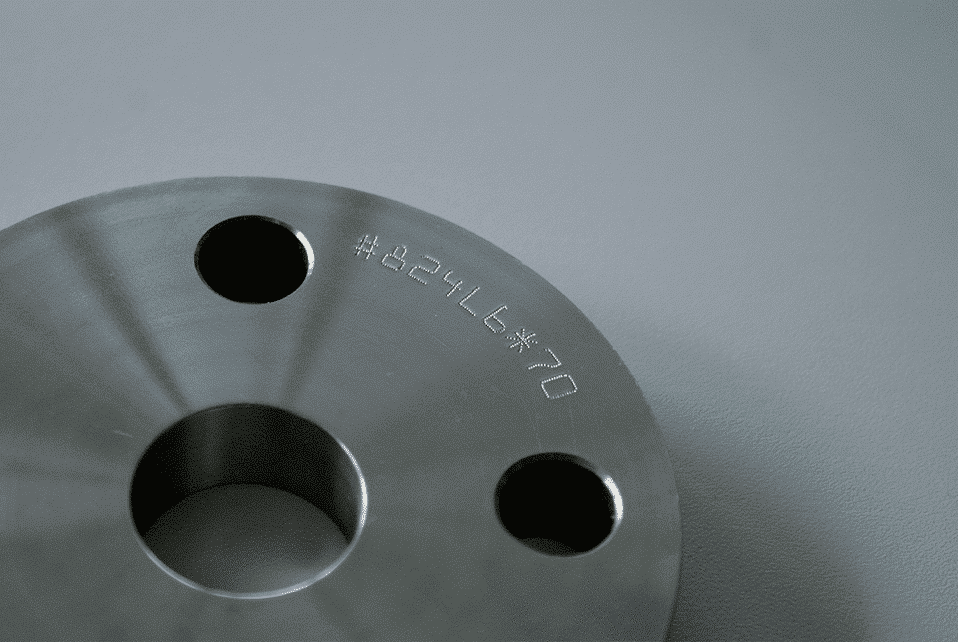

The 3D Mark, excellence through innovation

Thanks to 3D Mark technology, Technomark offers intelligent industrial marking. Regardless of the differences in levels between the part and the stylus, the quality of the dot peen marking is guaranteed with Intelligent Driving Impact (IDI). IDI Mark renders quality marking and IDI Track allows to anticipate production stoppages thanks to automatic preventive maintenance functions.

Find out more

VERSATILITY

A system designed to adapt to all industries

MYTECHNOMARK

A question? Need assistance?

All the answers are on your professional space

Technical support, demonstration videos, documentation, access all M4 Inline resources

Discover M4 Inline at your place

One of our advisers will come to your place for a real-life test

Try M4 Inline with us

Our advisers welcome you in our showroom or at one of our partners

FEASIBILITY STUDY

FEASIBILITY STUDY SHOWROOM DEMONSTRATION

SHOWROOM DEMONSTRATION MARKING SAMPLES

MARKING SAMPLES ONSITE TESTING

ONSITE TESTING FACTORY MAINTENANCE CONTRACT

FACTORY MAINTENANCE CONTRACT HELPLINE

HELPLINE MAINTENANCE CONTRACT

MAINTENANCE CONTRACT EQUIPMENT LOAN

EQUIPMENT LOAN REPAIR

REPAIR