Industrial Marking Solutions for Automotive Applications

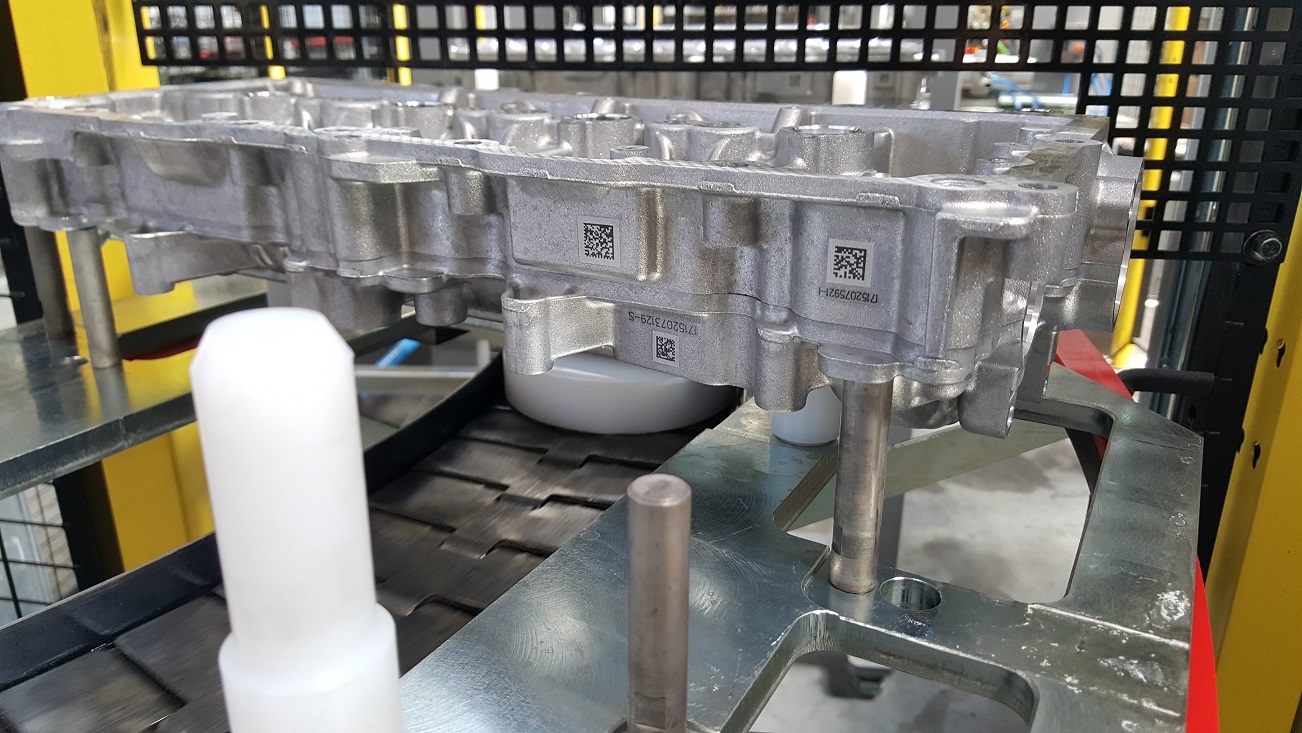

Technomark has specialized in industrial part marking since 2000, providing multiple solutions for dot-peen marking machines and industrial laser marking machines. The result is a permanent, robust, and machine readable ID for increased security and improved quality control.

Technomark has applied state-of-the-art marking techniques to improve automotive production processes. Automotive manufacturers are required to mark the different parts of the vehicle with identification codes like the:

- AIAG B-4 parts identification & tracking application standard

- AIAG B-17 2D direct parts marking guideline

Technomark has a wide range of equipment ideal for this purpose, including automotive laser marking machines and dot peen marking machines.

Automotive traceability requirements can be an annoying snag in the production process. Technomark equipment empowers companies to obtain reliable and rigorous information:

- Defective parts and containment

- Specific part characteristics after measurement

- Data exchanges between customer and supplier

- Inventory management

- Quality control

- Error-proofing

What Code Is Best For Automotive Marking?

Across manufacturing industries, the most common 2D code is datamatrix. It possesses a high density data storage, and allows a large number of characters to be encoded in a very compact space.

Since machines can read this code, human error is minimized. The data redundancy allows the code to be read even when it’s partially damaged. This feature is perfect for automotive traceability requirements,where parts may be dirty or subject to wear and tear.

2D datamatrix code can contain valuable information like:

- Production details

- Date of manufacture

- Serial numbers

Plus, these markings are easily readable (visually or by a machine during an automated process), as well as highly durable and sustainable.

Learn More About Traceability in the Automotive Industry

Want to learn more about how industrial part marking systems can improve automotive manufacturing processes, decrease total cost of ownership, and increase ROI? Check out our case studies below!

OUR BIGGEST CLIENTS IN AUTOMOTIVE MARKING Relying on our 18 years of experience, we have been able to work with the biggest companies in the automotive field