TEMPO

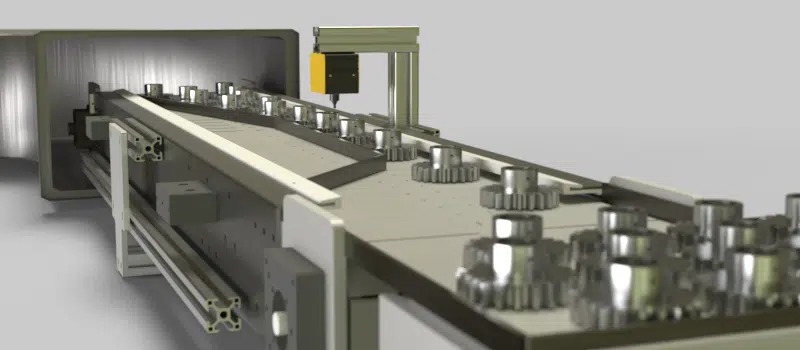

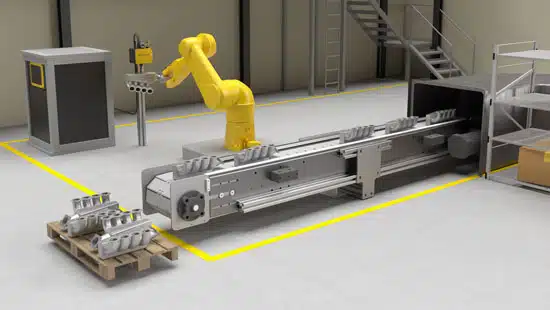

Integrable – integrated dot peen marking machine

Dedicated solution for automated industrial production

For technical documentation, visit the extranet!

Discover Tempo from the Inline.series, our new electromagnetic dot peen marking machine, specially designed for automated environments. Ideal for production lines, this machine offers simplified installation thanks to its versatile marking head, which can be mounted on three sides, and its rack-mountable controller. Its ergonomic software, developed internally, facilitates configuration. The solution is equipped with a 16-channel card and Ethernet TCP-IP connectivity (Profinet and Ethernet IP). Moreover, an integrated maintenance warning and prevention system ensures smooth, uninterrupted production.

Why is TEMPO made for you?

Easy to integrate

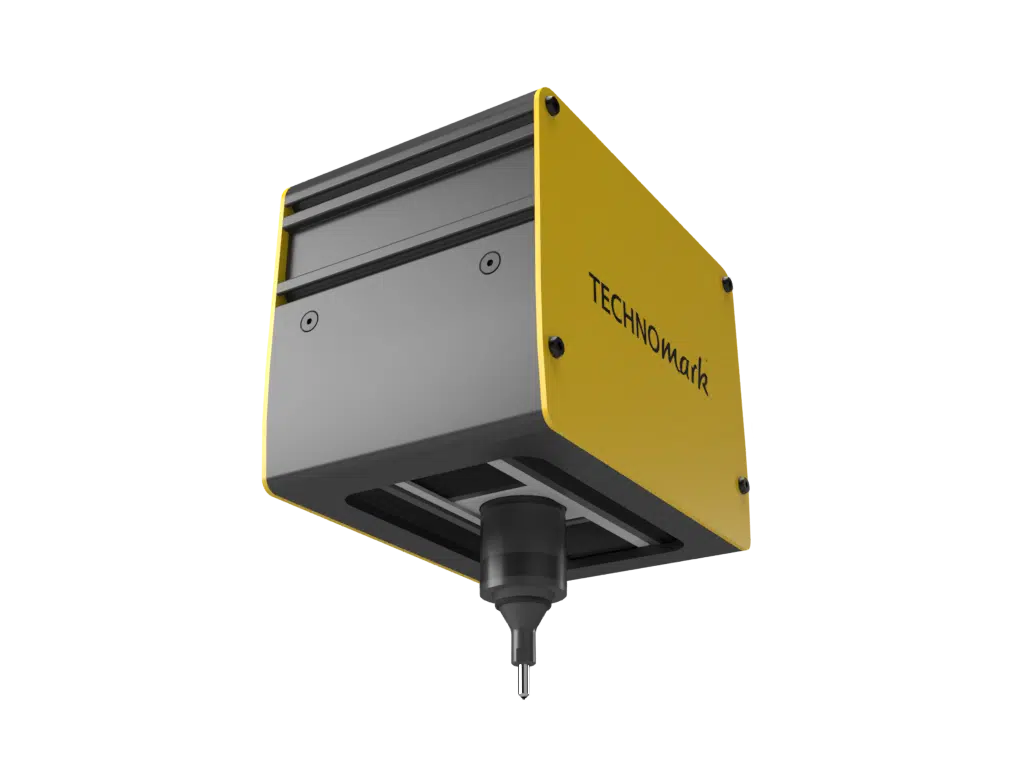

Tempo is characterized by its exceptional ease of integration and very compact design. This machine is quick and easy to install, thanks to its three-sided fixable marking head and rack-mountable controller. Moreover, its removable and lockable cables and 360° positioning further simplify installation, ensuring simple integration into any industrial environment.

MEDIUM AND LARGE SERIES

PARTS OF ALL SIZES

360° USE

MARKING ON NON-FLAT SURFACES

HIGH PERFORMANCE 24/7 MARKING

PREVENTATIVE MAINTENANCE

Flexibility to boost performance

Compact, 360° integration

- Dimensions without impact unit 170 x 132 x 124 mm

- 3 mounting faces available

- Installation in any directions to suit your environment

Robust

- Anodized aluminum frame

- Painted steel covers

- Protective cover against dust and abrasive products

High-performance

- 30% faster than our previous integration model

- Marks 3 characters per second

- High marking accuracy even at high speeds

- Engineered for continuous operation

Advanced settings

- Easy to configure

- Ajustable marking window size

- Programmable pathways for stylus to avoid obstacles

- Origin selection

Rack-mount and panel-mount controller

- Controller installation on a standard rack

- Integrate into any environment

- Controller mounting compatible with VESA 100 support

Connectivity

- 3 USB ports for connecting peripherals (keyboard, mouse, 2D barcode readers)

- 2 RJ45 ports for network connection via Ethernet TCP-IP (Profinet and Ethernet IP)

- 16 input/output channels

Complete and intuitive software

| 12 inputs types : | 14 output types : |

| Start marking | Machine ready |

| Pause | Marking in progress |

| Start marking test | Test in progress |

| Stop | End of marking |

| Open marking file | Marking paused |

| Close marking file | Error |

| Wait for external input | Machine in origin position |

| Reset serial number | Lubrication required |

| Increment serial number | Sharpening required |

| Return to original position | Maintenance required |

| Acknowledge error | Copy input status |

| Part present | Empty variable |

| File empty / No file open | |

| Output control in marking cycle |

A wide range of features

- Slave mode or stand-alone mode operation

- Management of global variables (machines) and local variables (files)

- Maintenance module

- Real-time marking information

- 4 access modes: administrator, supervisor, production and auto

- Multilingual software

- Easy Shift function

- Impact unit travel management

- Network connection via Ethernet TCP IP

- Integrated switch function

Technical specifications

| General dimensions (without impact unit) | 170x132x124 mm |

| Wiring | 10m cable length, removable and lockable |

| Marking window size | 30×60 mm |

| Marking speed | Up to 3 characters per second |

| Installation | 3 fixing faces and 360° use |

| Power supply | 24VDC 10A |

REQUEST YOUR FREE

quote – DEMO – DOCUMENTATION