Industrial Part Marking Types

Direct part marking is a method relied on by many companies to provide clear and long-lasting identification for their parts. This is due to the increasing need for part tracking across its lifespan, and the ability to address concerns with specific part lots as necessary.

Both dot peen marking systems and laser marking systems are efficient methods of providing industrial marking solutions for production lines. However, it is important to consider the type of marking you will be using and the right location on the part to apply the mark. This gives you a better starting point for considering the right industrial part marking solution.

Four common part marking types include:

- Alphanumeric marking

- Automatic alphanumeric marking

- 2D codes marking

- Logo marking

Learn more about your specific part marking solution

Direct Part Parking Types | The Breakdown

Both dot peen marking and laser marking offer a variety of marking types. This can be a result of the files needed to control the marking process or the fonts needed and the adjustments you might require to fit your specific marking requirements.

Alphanumeric Marking

Alphanumeric code is made up of a string of numbers and/or letters. This is typically used for serial numbers and intended to prevent fraud. The alphanumeric marking format is most commonly used for serial numbers, such as the VIN number on vehicles.

Our dot peen marking systems feature a number of classic fonts, as well as forgery-proof fonts (OCR-A, OCR-B). These are commonly employed to mark alphanumeric codes in the aerospace industry.

Our laser engraving marking systems offer a wider range of possibilities, and all ttf fonts can be used to create alphanumeric codes.

2D Code Marking

In Europe and the USA, Datamatrix marking is the universally recognized encoding technique for DPM (Direct Part Marking). The Datamatrix code is a 2D code useful for large information quantities. Its use is widely democratized in many industrial sectors, but varies from continent to continent.

This type of 2D code complies with the ISO / IEC 16022 standard, and is therefore freely available in the public domain. QR codes are also used in Asia, particularly Japan.

Logo Marking

Great for branding and personalization, Logo Marking provides personalization and the ability to meet manufacturing standards.

Logo marking works well for a variety of industries, including:

- Automotive

- Aerospace

- Metallurgy

- Energy

- Medical

By combining laser marking and dot peen technologies, we offer a series of significant advantages for professionals.

Automatic Alphanumeric Marking

As noted in the alphanumeric marking section, time stamps are the most common data that can be set for automatic input. Whenever marking begins, this data is adjusted based on the file that is used.

Both laser engraving and dot peen marking systems have automatic time stamping features that allow you to integrate this into your manufacturing and traceability processes. Many forms of time stamps can be set.

Part Marking Locations

The location of the mark on the product’s surface is another important consideration. Not only should the location of the mark be carefully chosen, but you should also be careful to consider the orientation of the mark as well. This improves the readability and the potential for efficient scanning for 2D codes. With these in mind, multiple options are available for marking location and orientation, including:

Straight Marking:

The most common choice for marking orientation is straight marking, which presents the mark horizontally from left to right.

Angular Marking:

This approach is used when the product does not have a smooth surface long enough for the mark to be presented horizontally. The mark can be adjusted up to 360° to provide the best positioning for clarity.

Radiant Marking:

This marking follows the circular path on products that provide one, i.e. the outline of a cylinder

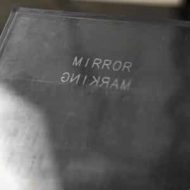

Mirror Marking:

The mark placement on these products (typically translucent parts) allows for clear readability once the part is turned over.

Marking on Cylinders:

Cylindrical surfaces can be marked either on the circumference or on the tangent with this type of marking.

Multi-Level Marking:

This option permits marking on different surface heights (useful when a lot of information needs to be marked on a single part)