What Is Dot Peen Marking?

Ask anyone inside the industrial manufacturing industry – part-marking is crucial to component traceability when working with large quantities. And while several different types of part-marking exist, Dot Peen marking technology has been a preferred solution for many years.

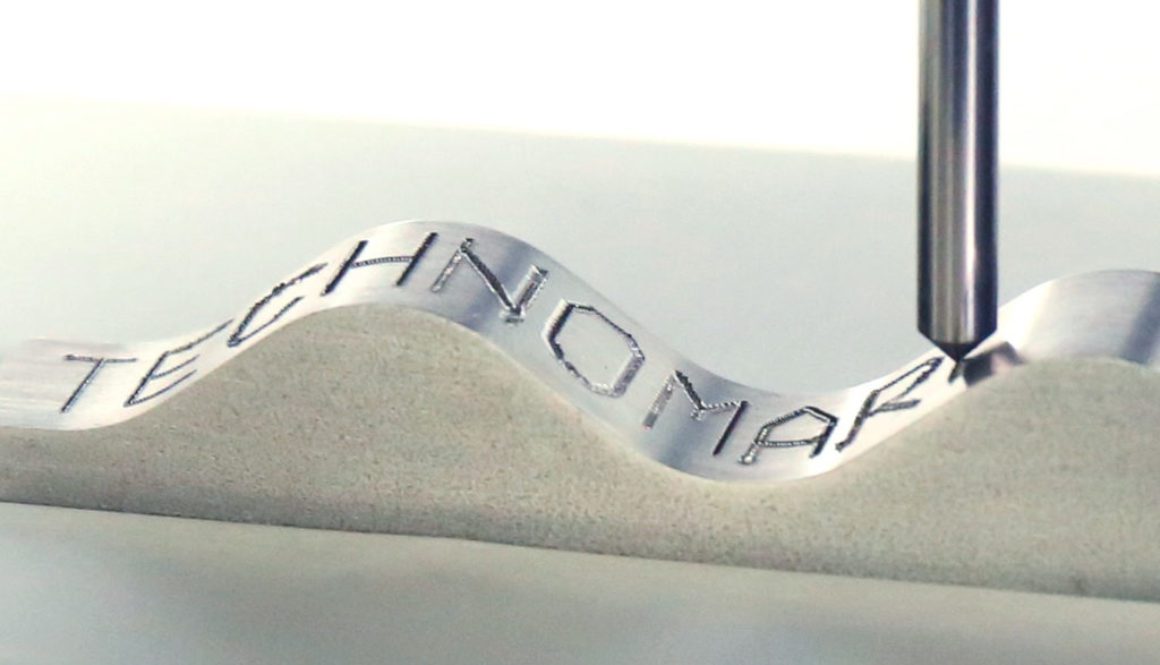

At a high level, Dot Peen marking machines use either electromagnetic or pneumatic force to rapidly oscillate a stylus, in turn indenting the marks onto the surface of the part.

One of the advantages of Dot Peen is that it’s very flexible and can be used in either manual or fully automated production lines. A lot of the applications Dot Peen serves are manual applications, however, with modular Dot Peen systems, you can start with a portable system and later convert it to an in-line system for integration with fully automated production lines.

The Basics | What is Dot Peen Marking?

If you took apart a Dot Peen machine, one of the most important components you would find is a carbide or diamond-tip stylus.

The Dot peen process is considered a “low-stress” marking method because the mark is generated via material displacement rather than material removal. The carbide stylus strikes the material surface to produce the mark via a series of cold-formed stamped dots. Compared to Laser Marking Systems, Dot Peen does not induce thermal shock to the part surface since the material is cold-stamped rather than super-heated to produce the mark.

Dot Peen systems are commonly used by manufacturers in the aerospace and oil & gas industries where low-stress marking is required, such as tubular and flow control products that are exposed to extreme pressure differential in the oilfield.

Dot Peen marking is viable for material hardness up to 63 HRC. Typically, when a part hardness is greater than 63 HRC, laser marking systems are recommended.

All of Technomark’s Dot Peen machines rely on an electromagnetic solenoid to actuate the marking stylus. Dots are plotted in an X/Y plane via electronic control for precise placement of the Dot pattern. Using electromagnetic force versus pneumatic also provides a greater level of control of both the depth of the mark as well as the ability to mark contoured or complex surface.

Dot Peen Marking: Component Traceability In Action

Dot Peen marking machines are utilized in almost every industrial-goods manufacturing operation, including:

- Automotive

- Oil and Gas (pipes, fittings valves, other)

- Aerospace

- Defense

- Metalworking (general purpose)

While these machines can run in-line and handle large quantities in an automated production environment, most are operated manually using a battery pack to go mobile.

The best Dot Peen marking machines utilize a fully electric design and that doesn’t require compressed air to operate. All Technomark Dot Peen marking machines feature an Intelligent Driving Impact (IDI) function that allows for marking on many different materials and finishes. The IDI function automatically adjusts and levels the stylus to the workpiece. Whether the part has a curved, wavy, or complex geometry, the stylus will follow the contour of the marking surface while maintaining a constant depth of high-quality marking throughout.

When structural integrity is crucial, Dot Peen marking provides a low-stress marking solution that removes no material during the part marking process.

Why Choose Dot Peen Marking

One of the biggest benefits of a Dot Peen Marking Machine is its ability to efficiently produce marks compared to other marking systems. Other benefits of Dot Peen machines include:

- Portability: battery-operated systems are ergonomic and perfect for smaller-scale operations or marking of large, heavy parts that cannot be transported to a fixed location for marking

- Versatility: state-of-the-art Dot Peen marking systems are modular and can start with a portable or manual marking system that can later be adapted to a fully automated production line

- Ease of use: Dot Peen machines are easy to program and do not require any advanced computing knowledge or technical training.

- Permanency: Dot Peen marking process yields a permanent, indelible mark that can withstand harsh operating environments

- Economical: Compared to other marking systems, Dot Peen systems are typically less than $10,000.

Integrating a dot peen marking machine into your production line will improve the productivity and quality of the part-marking process.

New and exciting dot peen innovations are coming this fall. Be on the lookout for machines that feature:

- Wireless connectivity between marking head and control (Network-able devices that are able to communicate to other devices through wireless communications)

- On-board diagnostic tools to help the operator know when it’s time for scheduled maintenance — protecting your investment.

If you have questions regarding Dot Peen machines or any part marking machines, contact us today. At Technomark North America, we have the experience to help you get the best solutions for your industrial marking needs.

(Editor’s Note: This blog was originally published in September 2021 and was updated in December 2023.)