10 Things to Know About Dot Peen Marking Machines

The use of dot peen marking machines is prevalent in various industries. This popularity is due to the number of different configurations possible, including mixed-use where portable can become integrated in a short amount of time.

What is Dot Peen Marking?

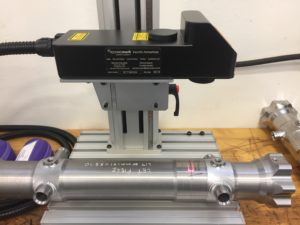

Dot peen marking is a process utilizing either electromagnetic or pneumatic force to rapidly vibrate a stylus and indent a predetermined system of marks into a surface. This process provides a reliable marking method for industries where precise tracking processes are required and extended product ID readability is required.

Dot Peen Marking: 10 Manufacturing Benefits

Numerous industries have set regulations for product IDs regarding both longevity and readability. The automotive industry, for example, integrates dot peen marking systems into its production line, providing the opportunity to mark different types of parts with an ID that will be readable and last.

There are 10 notable features of dot peen marking machines:

- Versatility

- Micro-percussion

- Industry 4.0

- Data storage

- Marking options

- Capable of marking various materials

- Low maintenance

- No waste generated

- Marks uneven surfaces

- Adaptable based on market needs

1. Versatility

A dot peen marking machine can be portable, which is ideal for marking large part batches, frames, or other large products. For marking and engraving small to medium-sized parts, the machine can be attached to a column base. This can be done quickly and efficiently, allowing you to integrate it into a line for mass production as well.

2. Longevity

This style of marking makes numerous impressions using a stylus to deform the material. The mark is permanent and will be readable for the life of the part. This method is increasingly popular for bicycles, aircraft parts, and VINs on vehicles.

3. Industry 4.0

Today’s industrial manufacturing is moving into its next iteration: Industry 4.0. This phase has a focus on real-time, connected interfaces that allow for external influence from a distance. The dot peen marking machine can be connected to the network to share information in real time. This also allows for external control and automation of the marking process.

The grid connection can also allow data compilation to ultimately anticipate maintenance needs, such as lubrication or part replacement.

4. Data Storage

Datamatrix has significant capacity allowing for up to 2335 alphanumeric or 3116 numeric characters in 1 cm² surface. This type of code also provides a reliable and readable mark, even with up to 20% deterioration.

5. Marking Options

There are numerous options for marking parts, available as needed and with minimal adjustment. These include:

- Alphanumeric

- 2D code

- Visuals

- Orientation and deformation

6. Capable of Marking Various Materials

Dot peen marking machines allow for marking a variety of materials, but there is a limit based on the durability of the material. Steel, aluminum, bronze, and carbide are only some of the materials that can be successfully marked by a dot peen marking machine.

7. Low Maintenance

The dot peen marking system utilizes a tungsten carbide stylus, which is long-lasting but does wear out over time. The continuous impact with durable materials means replacement is necessary at some point, and plans should be made accordingly. Another regular maintenance task is to reset the stylus spring, which is done at the time the stylus is replaced.

8. No Waste Generated

No fractures occur in the materials during dot peen marking, as the focus is creating a mark in the material without removing any layers. With no material removed, no waste material is generated.

9. Marks Uneven Surfaces

Dot peen marking can be done on non-flat surfaces. The machine can mark a surface with a difference of up to 5mm. Cylinders and angular surfaces can also be marked.

10. Adaptable Based on Product Requirements

Accessories accompany dot peen marking machines, expanding on their versatility. For products that require a more specific marking process, personalization of the dot peen marking process is possible.

The number of controller outputs is adaptable, and accessories such as a bellows (ideal for dusty environments) or a clamping system, are available to adapt the machine as necessary. The clamping system provides an opportunity to mark the median as well as the circumference of the product.

Dot Peen Marking Machines Deliver

Dot peen marking machines are efficient and versatile, providing options for both portable and integrated use. These machines are the solution to creating long-lasting marks with no materials removed from the product surface.

The integration of a dot peen marking machine into your mass production process can ensure your products effectively meet regulatory requirements.

Ready to Learn More?

Dot peen marking systems are versatile, up-to-date, and create little to no waste. For more information on the dot peen marking process, consider these resources:

Direct Part Marking 101 | Defense and Military Applications

10 Industrial Part Marking Considerations – TechnoMark

Marking Machines: Are They The Best Method For Your Materials? – TechnoMark