TECHNOMARK North America invites you to SOUTHTEC 2019

Booth: 1939

TECHNOMARK is a leading OEM of high performance industrial traceability solutions centered on two core direct-part-mark (DPM) technologies: dot peen and laser marking. TECHNOMARK’s modular design concept facilitates product integration with existing manufacturing processes while ease-of-use and system reliability maximize production uptime and lower total cost of ownership. Located in Conroe, Texas (40 miles north of downtown Houston), TECHNOMARK is the only OEM of industrial marking machines with North American headquarters in the south-central USA.

Products

GRAPHIX Laser Marking Workstation

GRAPHIX is an ideal solution for permanent marking of components in a low-volume, high-mix production environment. The space-saving, all-in-one design incorporates the laser marking head, embedded Windows PC, and electronic control system into a fully-integrated package that can be placed on a benchtop. Alternatively, the workstation can be placed on a mobile marking cart for deployment in a flexible manufacturing environment. An optional side-access opening permits insertion of bar stock, tubulars, or other oversize parts into the interior of the workstation enclosure for laser marking while maintaining a Class I safety rating. GRAPHIX is also available with standard and heavy duty rotary axis options that are plug-and-play and permit 360° component marking.

NEW for SouthTec 2019, TECHNOMARK has partnered with COGNEX to develop an integrated barcode reader package for the GRAPHIX laser marking workstation. To learn more, please see our announcement on LinkedIn at https://lnkd.in/eBR3RZp

The DataMan 370 series fixed-mount barcode readers solve challenging direct part mark (DPM) applications with advanced decoding algorithms, integrated lighting, and auto-focus liquid lens technology. To learn more about the DataMan 370, please visit COGNEX on the web at https://lnkd.in/e5mz_69

Available as an upgrade with the standard GRAPHIX laser marking system, TECHNOMARK lowers your Total Cost of Ownership (TCO) with an all-in-one solution for laser marking and reading 2D data matrix and QR codes marked directly onto high-value components for full item-level traceability.

M4 Inline – Integrated Dot Peen Marking System

M4 Inline comes standard with on-board PLC logic thanks to a 16-way user bus card, allowing the marking system to control other peripheral devices upstream and downstream from the marking process. The 16 discrete I/O points are fully digital and user-configurable according to the needs of a given production process, lowering total project cost by eliminating the need for an external PLC host control system. The all-electric design of M4 Inline also eliminates the need for compressed air, while TECHNOMARK’s patented IDI Mark feature permits marking of text onto curved or complex surfaces with even depth of marking and no character distortion. The compact marking head is ideal for mounting into tight spaces, while the machine control box can be rack-mounted in either a vertical or horizontal orientation.

An optional programmable linear index for the marking head is stepper motor driven for precision control and fully integrated with the user interface of the M4 Inline control box, accelerating the engineering development time on your next custom automation project. To see a demonstration video of M4 Inline, visit TECHNOMARK on the web here.

NEW for SouthTec 2019, TECHNOMARK has partnered with COGNEX to develop an integrated barcode reader package for the M4 Inline integrated dot peen marking system. The bar code reader package is based on the DataMan 260 fixed-mount ID reader and is driven by the on-board PLC logic of the M4 Inline control box for a complete DPM marking and reading solution. To learn more about the COGNEX DataMan 260 fixed-mount ID reader, please visit COGNEX on the web at https://www.cognex.com/products/barcode-readers/fixed-mount-barcode-readers/dataman-150-260-series

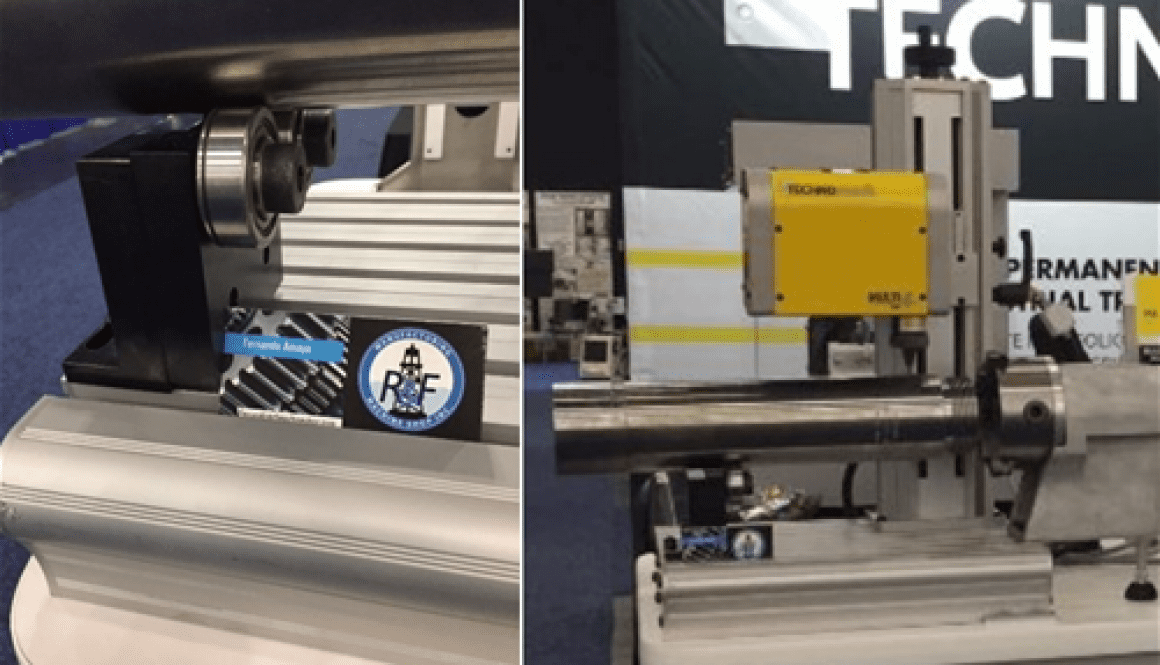

Multi-4 Modular 4-in-1 Dot Peen Marking System

NEW for SouthTec 2019, TECHNOMARK has partnered with R&F Machine Shop and Manufacturing of Conroe, TX to develop the new roller V-block part support for the Multi-4 dot peen marking system. When used with the Multi-4 High Capacity rotary D axis, the roller V-block part support provides additional stability for radial marking of tubular components measuring greater than 24″ in length and up to 5″ OD.

To learn more, please see our announcement on LinkedIn at https://www.linkedin.com/posts/ericmcdaniel_technomark-north-america-has-partnered-with-activity-6515789295201116160-T050