Technomark, global expert in intelligent solutions for traceability and industrial marking

Technomark: Laser & Dot Peen Marking Solutions

Industrial Direct Part Marking Equipment for Reliable Traceability

The right industrial marking system doesn’t just mark your products — it protects your brand, ensures compliance, and streamlines production.

Technomark provides advanced laser marking and dot peen marking solutions engineered for precision, durability, and efficiency. Whether you need a standalone marking device or a fully integrated, automated marking solution, our technology ensures permanent, high-quality part identification for even the most demanding industrial environments.

New products

Discover GX Small and XS Inline, the laser marking solutions of tomorrow

New and Ultra Compact

Laser Marking Station

New, Reduced Design

Laser Marking Equipment

Laser & Dot Peen Marking: Tailored to Your Needs

DESIGNING FOR THE APPLICATION OF TOMORROW

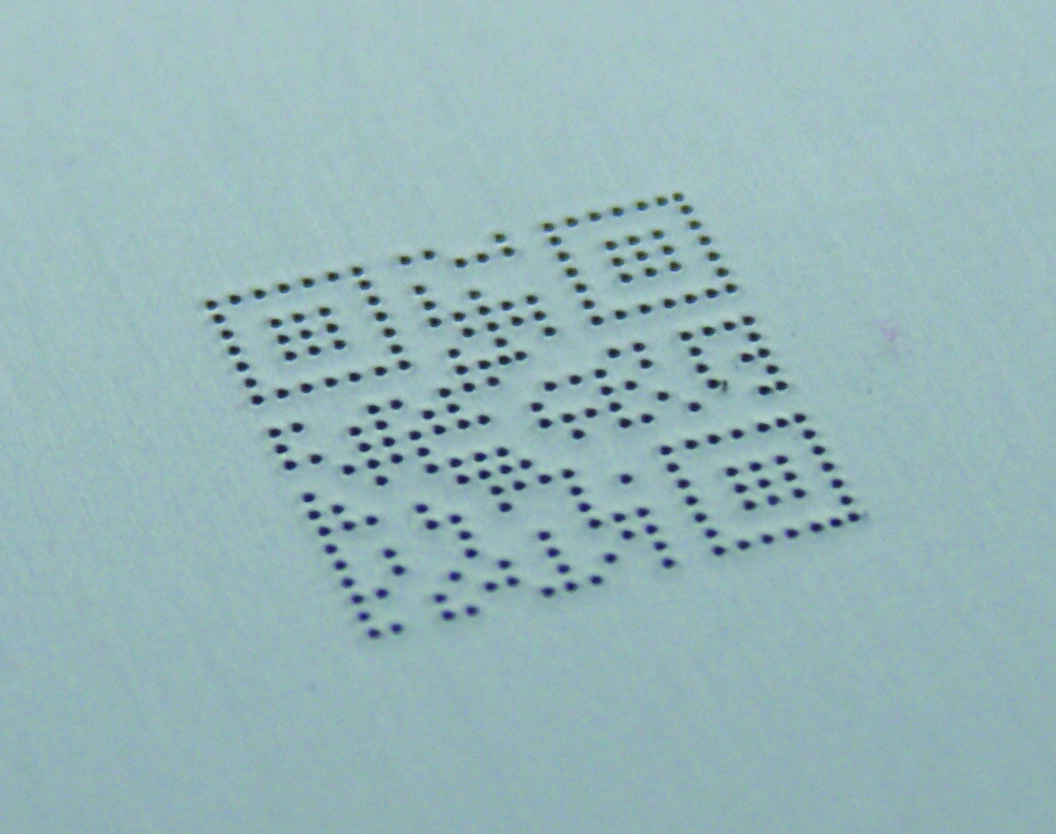

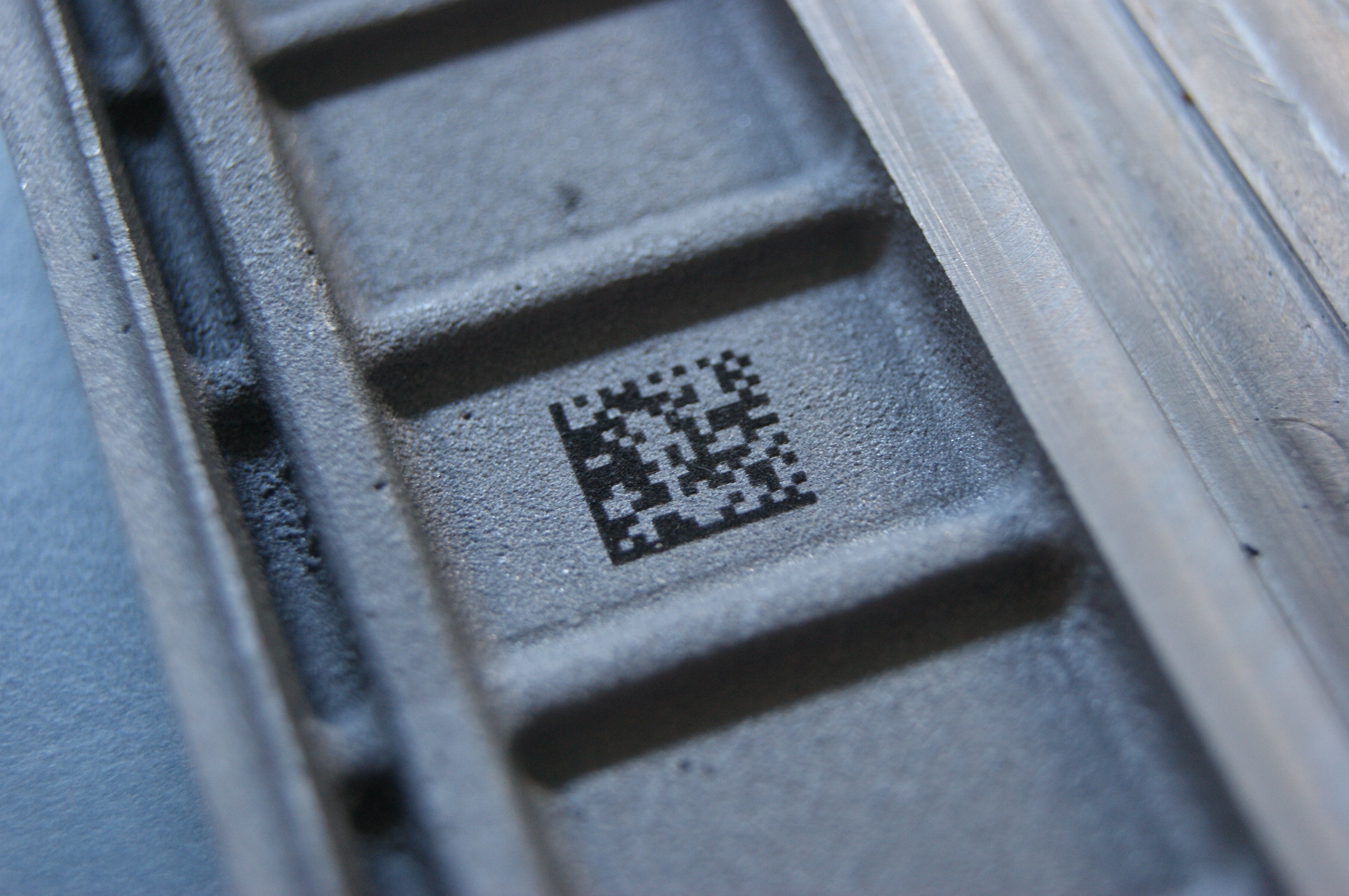

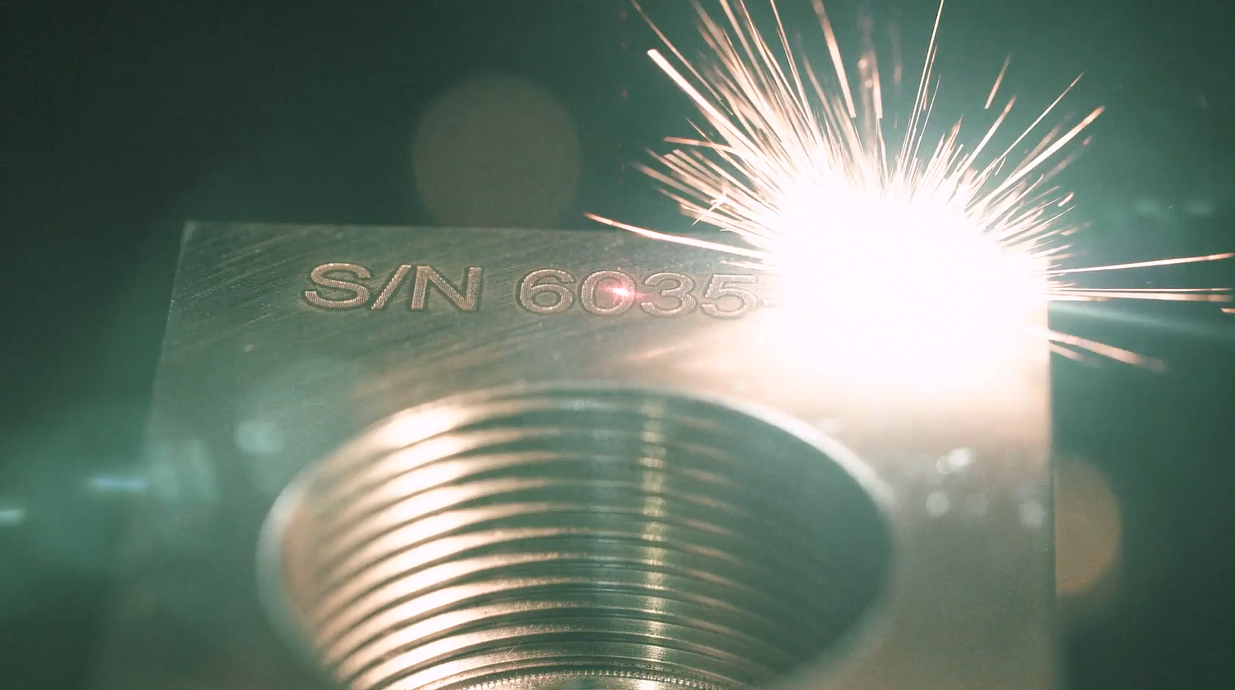

Laser Marking Solutions

Technomark’s industrial laser marking systems provide permanent, high-contrast marks on metal, plastic, and composites. From compact units to high-speed, automated marking solutions, we deliver the precision and efficiency modern manufacturers need.

Benefits of Laser Marking:

- Unparalleled precision and detail

- High-speed marking to increase throughput

- Non-contact process minimizes material stress

- Permanent, durable marks resistant to abrasion and chemicals

- Ideal for complex designs, barcodes, and data matrix codes

DESIGNING FOR THE APPLICATION OF TOMORROW

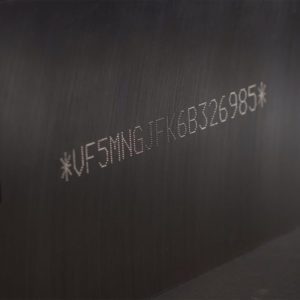

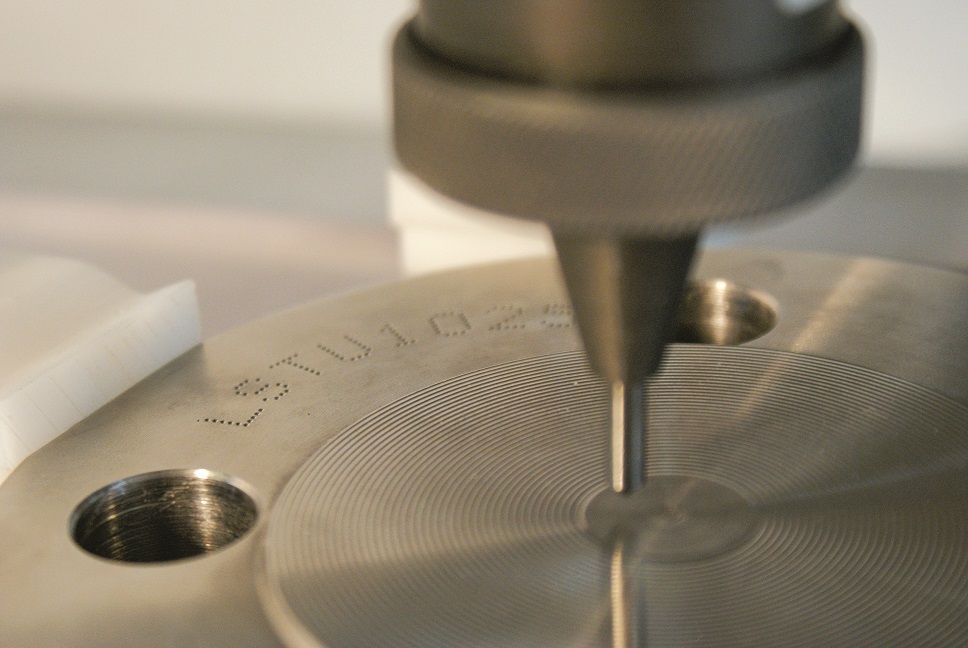

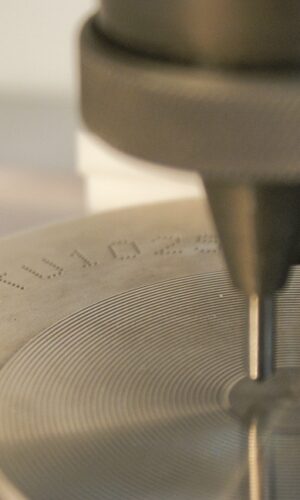

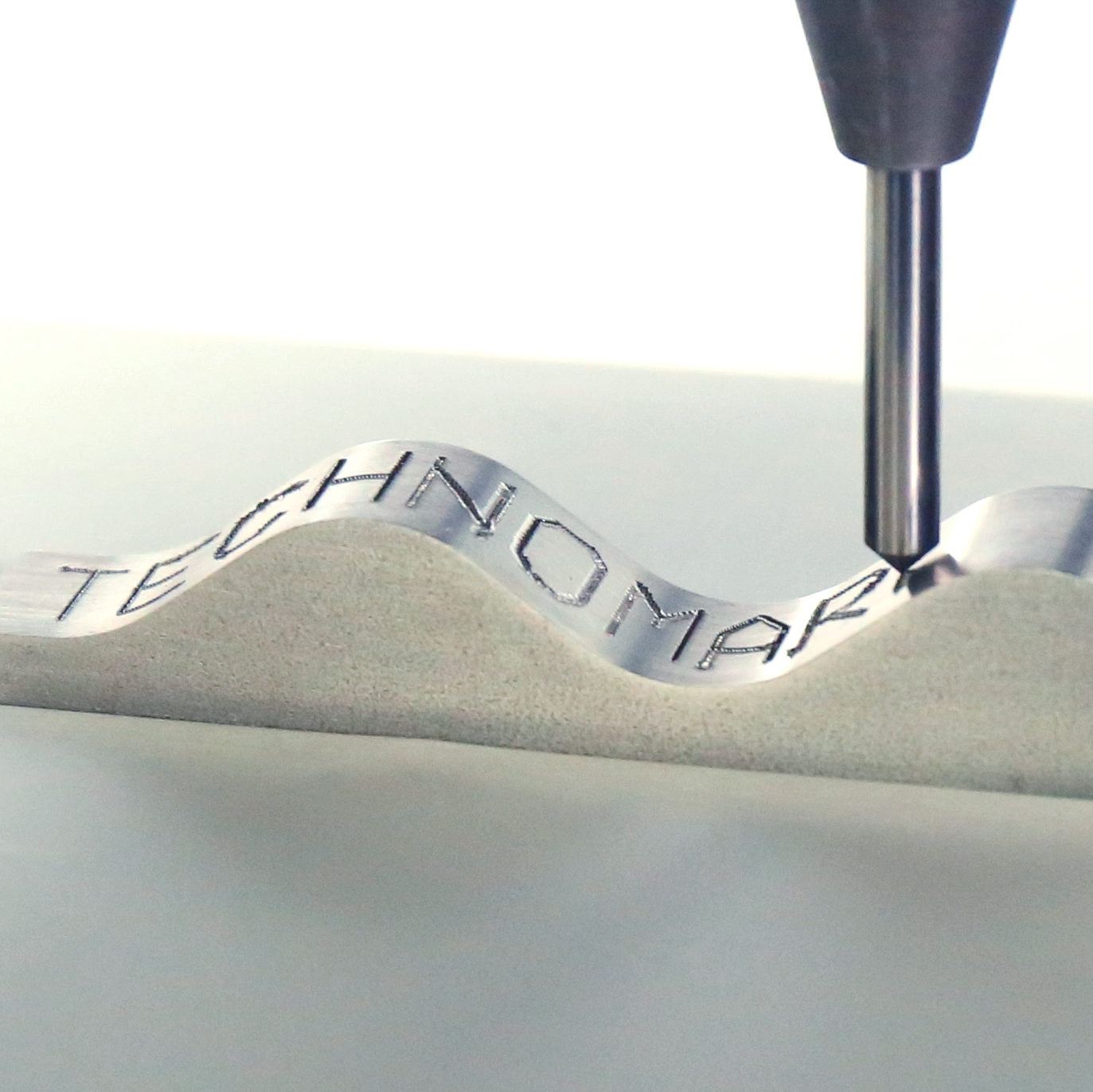

Dot Peen Marking Solutions

Technomark’s dot peen marking machines deliver deep, durable, and tamper-proof direct part marking. Our portable and automated solutions adapt to a variety of industrial marking needs, from serial numbers to tracking codes.

Benefits of Dot Peen Marking:

- Durable and tamper-proof marks

- Cost-effective marking solution

- Versatile marking on various materials

- Easy integration into production lines

- Ideal for deep marking and challenging surfaces

Tailored Marking Solutions for Every Industry

- Automotive

- Aerospace

- Medical Devices

- Electronics

- Oil & Gas

- Military & Defense

- Metalworking & Fabrication

WE GO FURTHER WITH YOU

Why Choose Technomark: Your Partner in Precision and Traceability

Component traceability is no longer just a good practice — it’s essential for success. That’s where we come in. Technomark is committed to helping you achieve flawless dot peen and laser marking solutions that ensure product traceability and meet industry standards.

Our systems have helped globally recognized manufacturers improve:

- Cost efficiency and reduce waste

- Quality control for top-notch products

- WIP tracking to streamline production

- Visibility across the supply chain

- Part authenticity for trusted products

- Error-proofing and assembly process improvements

- Warranty management for customer satisfaction

With over 19,000 systems in use worldwide, Technomark is your trusted partner for industrial traceability. Our permanent, clear markings ensure quality control every step of the way.

We put customers first with:

-

Feasibility studies and sample marking

-

Live demos and on-site testing

-

Custom solutions and training

-

Full support, helpline, and maintenance

-

Rental options for short-term needs

Resources

Learn More About Industrial Direct Part Marking With Our Blog

What Is Dot Peen Marking?

What Is Dot Peen Marking and How Is It Used? In industrial manufacturing, it’s key to track every component, especially when producing large volumes. The way you mark your parts is important, especially if they have to go through tough conditions or complicated supply chains. While there are many ways to mark industrial parts, dot […]

More Blog Content

A Manufacturer’s Guide to Laser Marking on Metal for Permanent Traceability

A Manufacturer’s Guide to Laser Marking on Metal for Permanent Traceability In manufacturing, traceability isn’t just a nice-to-have — it’s important for maintaining quality control, supply chain reliability, and regulatory compliance. When working with metal parts that operate in harsh industrial environments, you need a reliable, permanent identification method. That’s where laser marking on metal […]

More Blog Content

Laser Etching vs. Engraving: What to Know for Industrial Marking

Laser Etching vs. Engraving: What to Know for Industrial Marking Laser marking, which includes both laser etching and engraving, is a highly precise and reliable method for creating permanent markings on a wide range of materials. By using a focused laser beam, this laser technology alters the surface of the material to create everything […]

More Blog Content